Warehouse Solutions: Real Tips to Boost Your Operations

Ever wondered why some warehouses run like a smooth train while others feel stuck in traffic? The difference is often a mix of the right tools, smart layout, and a clear process. Below you’ll find easy‑to‑apply ideas that help you move from chaos to control.

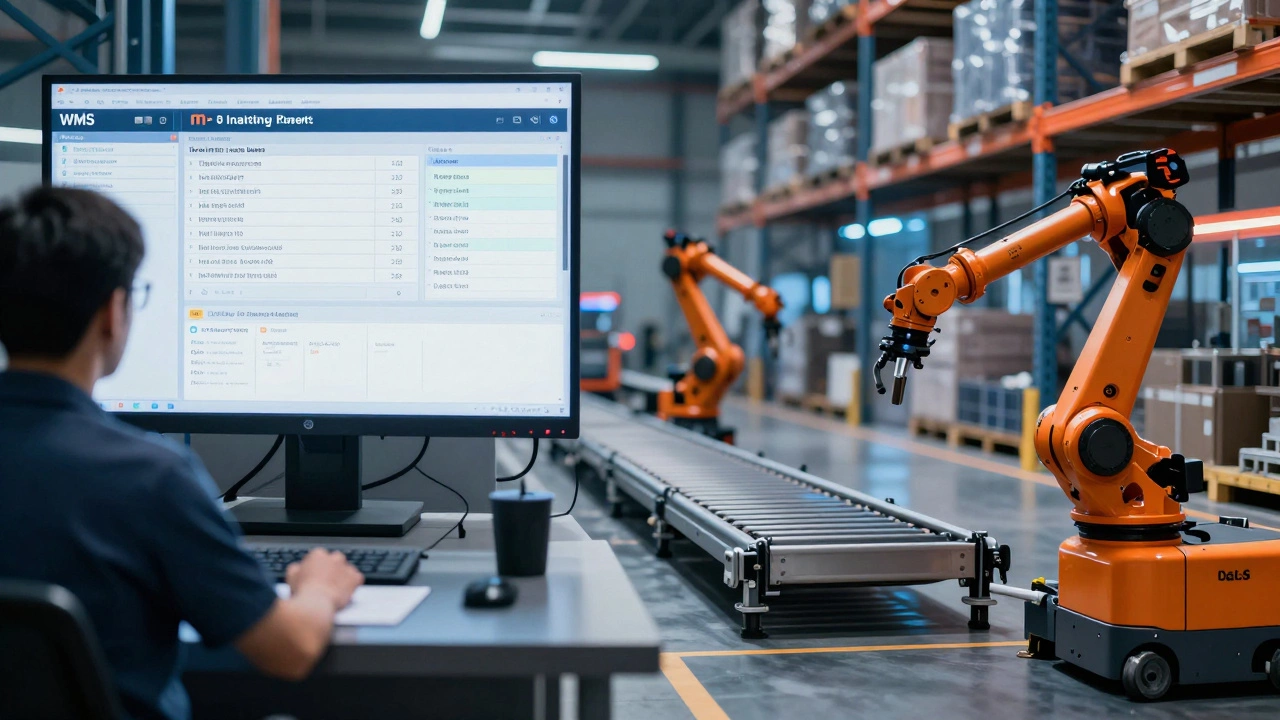

Pick the Right Management System

A Warehouse Management System (WMS) is the backbone of modern storage. It tracks every pallet, tells pickers where to go, and flags low stock before it becomes a problem. If you’re just starting, look for a cloud‑based WMS that offers real‑time data, barcode scanning, and simple reporting. For larger operations, a Tier‑1 WMS adds advanced analytics and multi‑site support.

When evaluating options, ask yourself:

- Does it integrate with my current ERP?

- Can I add modules as my business grows?

- Is the user interface easy for staff to learn?

Answering these questions saves time and money later.

Optimize Space and Flow

Space is money. Start by mapping your floor plan on graph paper or using a free online tool. Identify high‑traffic lanes, buffer zones, and dead‑ends. Keep fast‑moving items near the loading dock, and store slow‑turn stock in higher racks. Simple changes like adjusting pallet heights or adding a few narrow aisles can free up 10‑15% more space.

Don’t forget safety. Clear markings, proper lighting, and organized aisles reduce accidents and keep workers productive. A tidy warehouse also makes the WMS data more reliable because everything is where the system says it is.

Finally, consider technology upgrades that fit your budget. Barcode scanners, mobile pick devices, and basic robotics can cut picking time by half. Even a small investment in IoT sensors for temperature‑sensitive goods helps you avoid spoilage.

Putting these steps together creates a warehouse that runs smoother, costs less, and scales with demand. Start with one change—like a simple WMS trial—or rearrange a single aisle, then watch the improvement ripple through the whole operation.

Need more ideas? Browse our articles on specific topics such as “Types of Warehouse Management Systems,” “Modern Technologies in Warehousing,” and “Average Warehouse Rent in the US” to dive deeper into each area.

Your warehouse doesn’t have to be a guessing game. With the right system, smart layout, and a touch of tech, you can make every square foot work harder for you.

February 19, 2026

Evelyn Wescott

0 Comments

McDonald's doesn't own warehouses but depends on a global network of distribution centers to supply food, packaging, and equipment to its 40,000+ restaurants. Here's how their supply chain keeps meals consistent and fast.

January 12, 2026

Evelyn Wescott

0 Comments

Learn the four main types of warehouse management systems (WMS)-standalone, ERP-integrated, supply chain-connected, and cloud-based-and which one fits your operation best in 2026.

December 28, 2025

Evelyn Wescott

0 Comments

Learn how to choose a warehouse management system that cuts errors, saves time, and scales with your business. Avoid common mistakes and find the right fit for your operation in 2025.

December 18, 2025

Evelyn Wescott

0 Comments

Amazon is the world's largest warehouse company, operating over 1,100 fulfillment centers with 200 million square feet of space. Its integrated logistics system sets the global standard for speed and scale.

December 4, 2025

Evelyn Wescott

0 Comments

SAP powers modern warehouses by tracking inventory in real time, optimizing picking routes, and integrating with shipping and ERP systems. Learn how it reduces errors, cuts labor waste, and scales with your business.

December 1, 2025

Evelyn Wescott

0 Comments

A warehouse management system (WMS) tracks inventory and orders, while a warehouse control system (WCS) manages automated equipment. Learn how they work together-and when you need one or both.

November 17, 2025

Evelyn Wescott

0 Comments

A warehouse isn't the biggest player in logistics. Distribution centers, fulfillment hubs, and supply chains handle far more volume, speed, and complexity. Learn what's bigger-and why it matters for your business.

November 8, 2025

Evelyn Wescott

0 Comments

A smart warehouse management system uses real-time data, automation, and AI to track inventory, optimize picking, and reduce errors. Learn how it works, who uses it, and why it’s essential for modern logistics.

October 26, 2025

Evelyn Wescott

0 Comments

Master Data Management (MDM) is the backbone of accurate warehouse data. Learn what MDM is, why it matters for warehouses, how it works, and steps to implement it successfully.

October 14, 2025

Evelyn Wescott

0 Comments

Learn practical steps to identify, analyze, and fix common warehouse problems using layout tweaks, technology, safety protocols, and performance monitoring.

August 5, 2025

Evelyn Wescott

0 Comments

Explore the four types of warehouse management systems, understand how each fits different businesses, and learn tips for picking the right WMS.

June 12, 2025

Evelyn Wescott

0 Comments

This article breaks down what SAP means in the warehouse world, how it changes daily operations, and why so many companies rely on it. You’ll get clear answers about what SAP actually does and how it fits into modern warehouse life. If you’re tangling with inventory, shipping, or trying to cut mistakes, you’ll find practical info here. Packed with real-world examples and tips, it’s designed for anyone curious about streamlining warehouse work. By the end, you’ll know if SAP makes sense for your own warehouse needs.