McDonald's Delivery Frequency Calculator

Estimate how often your McDonald's restaurant receives ingredient deliveries based on location and customer volume. This tool reflects the article's explanation of McDonald's distribution network.

When you order a Big Mac, fries, and a Coke, you don’t think about where the ingredients came from. But behind every meal is a complex network of warehouses, trucks, and distribution centers that keep McDonald’s running. So, does McDonald’s use warehouses? Yes-and they rely on them more than most people realize.

McDonald’s Doesn’t Own Warehouses, But It Uses Them Daily

McDonald’s doesn’t build or operate its own warehouses. Instead, it works with third-party logistics partners who manage the storage and delivery of food, packaging, and equipment. These partners handle everything from frozen beef patties to napkins and fryer oil. The company’s model is built on outsourcing, which lets McDonald’s focus on branding, training, and store operations while experts handle the physical supply chain.

Think of it like this: McDonald’s is the conductor of an orchestra. The musicians-the warehouse operators, food processors, and transport companies-are the ones actually playing the notes. Without them, the music stops.

How the Supply Chain Is Structured

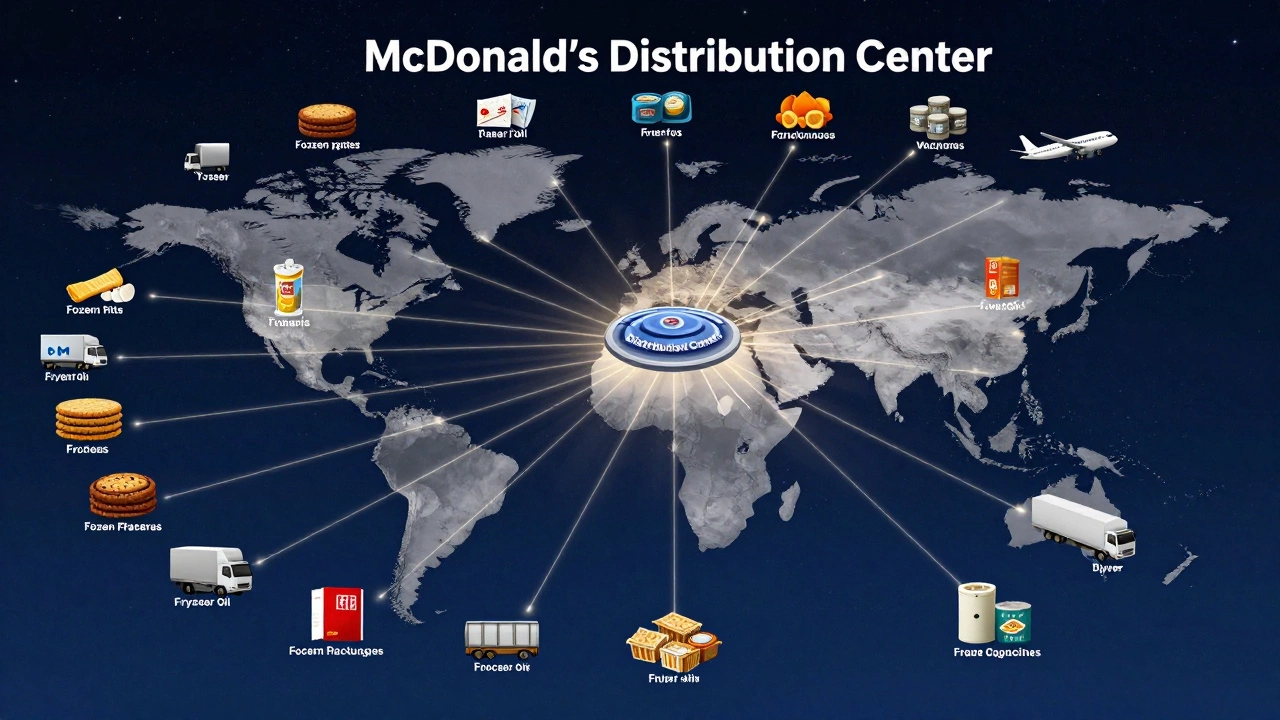

McDonald’s supply chain is split into three main layers:

- Food producers-companies like Tyson Foods, JBS, and McCain Foods that grow, raise, or process ingredients.

- Distribution centers-large warehouses that receive bulk shipments and sort them into store-specific orders.

- Delivery fleets-trucks that deliver goods to individual restaurants, often multiple times a week.

Each layer has its own warehouse system. For example, frozen food goes to climate-controlled facilities that maintain temperatures below -18°C. Fresh produce like lettuce and tomatoes is stored in refrigerated centers with humidity controls. Even the packaging-boxes, wrappers, cups-comes from dedicated warehousing hubs that stock millions of items.

There are over 100 distribution centers across the U.S. alone, and hundreds more globally. These aren’t small storage units. Many are bigger than 10 football fields and operate 24/7. They use automated sorting systems, barcode tracking, and real-time inventory software to ensure no restaurant runs out of buns or ketchup.

Why Warehouses Are Critical for Fast Food

Speed isn’t just about how fast a burger is made-it’s about how fast the ingredients get there. A McDonald’s in Ohio needs the same quality beef, buns, and cheese as one in California. That’s only possible with centralized warehousing.

Without warehouses, restaurants would have to order directly from dozens of suppliers. Imagine a manager calling 15 different companies every week to order fries, napkins, and milkshake mix. It would be chaotic, expensive, and unreliable.

Warehouses solve this by consolidating orders. One truck can deliver 30 different items from one warehouse to 10 restaurants in a single trip. That cuts costs, reduces waste, and ensures consistency across every location.

Temperature Control: The Hidden Infrastructure

Not all warehouses are the same. McDonald’s uses specialized cold chain logistics. Frozen items like patties and chicken nuggets need to stay below -18°C from the moment they leave the factory until they’re cooked. Refrigerated items like dairy and produce hover around 2-4°C. Even the packaging materials are stored in dry, climate-controlled zones to prevent warping or contamination.

These facilities have backup generators, redundant cooling systems, and real-time temperature sensors. If a freezer fails, alarms trigger immediately. Some centers even use AI to predict when equipment might fail based on vibration, noise, and power usage.

It’s not just about keeping food cold-it’s about keeping it safe. The FDA and USDA require strict documentation for every shipment. Warehouses log every temperature reading, every truck departure, and every delivery receipt. If a foodborne illness outbreak happens, they can trace every ingredient back to its source in under 2 hours.

How Often Do Warehouses Ship to McDonald’s?

Most McDonald’s locations receive deliveries 3 to 5 times a week. High-volume stores in cities might get deliveries daily. The timing is calculated down to the hour.

Here’s how it works:

- Each restaurant reports inventory levels daily using a tablet system.

- The system sends alerts to the distribution center when stock is low-like if they’re running out of cheese slices or soda syrup.

- Warehouses use algorithms to group orders from nearby restaurants into efficient routes.

- Trucks leave the warehouse at 2 a.m. to avoid traffic and deliver before the morning rush.

This system means a restaurant in Texas won’t run out of fries on a Friday night. It also means less food waste. If a store doesn’t order enough, the warehouse doesn’t ship it. No guesswork. No overstock.

What Happens During a Supply Chain Crisis?

In 2021, a major trucker strike in the U.S. caused delays across the fast food industry. McDonald’s warehouses responded by shifting to rail transport for bulk items and using local distributors for emergency deliveries. In 2022, when a fire took out a key beef processing plant in Kansas, McDonald’s switched to backup suppliers within 72 hours.

These responses don’t happen by accident. Warehouses maintain backup inventory for top-selling items. They keep 2-3 weeks’ worth of buns, patties, and packaging on hand-not just for daily use, but for emergencies. That’s why, even during labor shortages or weather disruptions, most McDonald’s restaurants stay open.

Global Differences in Warehouse Use

McDonald’s adapts its warehouse network to each country. In Japan, they use smaller, urban distribution centers because of space limits and dense population. In Australia, they rely on regional hubs that serve hundreds of stores across vast distances. In India, where beef isn’t sold, warehouses focus on chicken, paneer, and vegetarian patties.

Even packaging varies. In Europe, warehouses store compostable wrappers. In the U.S., they stock recyclable paper bags. The systems are flexible, but always centralized.

What Would Happen Without Warehouses?

If McDonald’s suddenly lost all its warehouse partners, every single restaurant would have to order directly from suppliers. The cost of shipping would triple. Inventory errors would spike. Some stores might run out of buns for days. Others would have 10,000 extra napkins they don’t need.

Consistency would vanish. A Big Mac in Chicago wouldn’t taste the same as one in Miami. The brand would lose its biggest advantage: reliability.

Warehouses aren’t just storage units. They’re the silent backbone of McDonald’s global success.

Other Fast Food Chains Do the Same

McDonald’s isn’t unique. Burger King, Wendy’s, and Taco Bell all use the same model. Even Starbucks relies on regional warehouses for coffee beans, cups, and syrups. The difference? McDonald’s scale is unmatched. With over 40,000 locations worldwide, their warehouse network is one of the largest food distribution systems on the planet.

It’s not glamorous. No one posts TikToks about frozen meat pallets. But without these warehouses, your lunch wouldn’t be ready in under 5 minutes.