Warehouse Efficiency Calculator

Calculate Your Potential Savings

See how much your warehouse could improve with a smart WMS system based on your current operations

Your Potential Improvements

Enter your current metrics to see your potential improvements.

Source: Based on real-world implementation data from the article: Smart WMS systems can reduce picking errors by 40%, improve fulfillment speed by 25%, and increase space utilization by 30%.

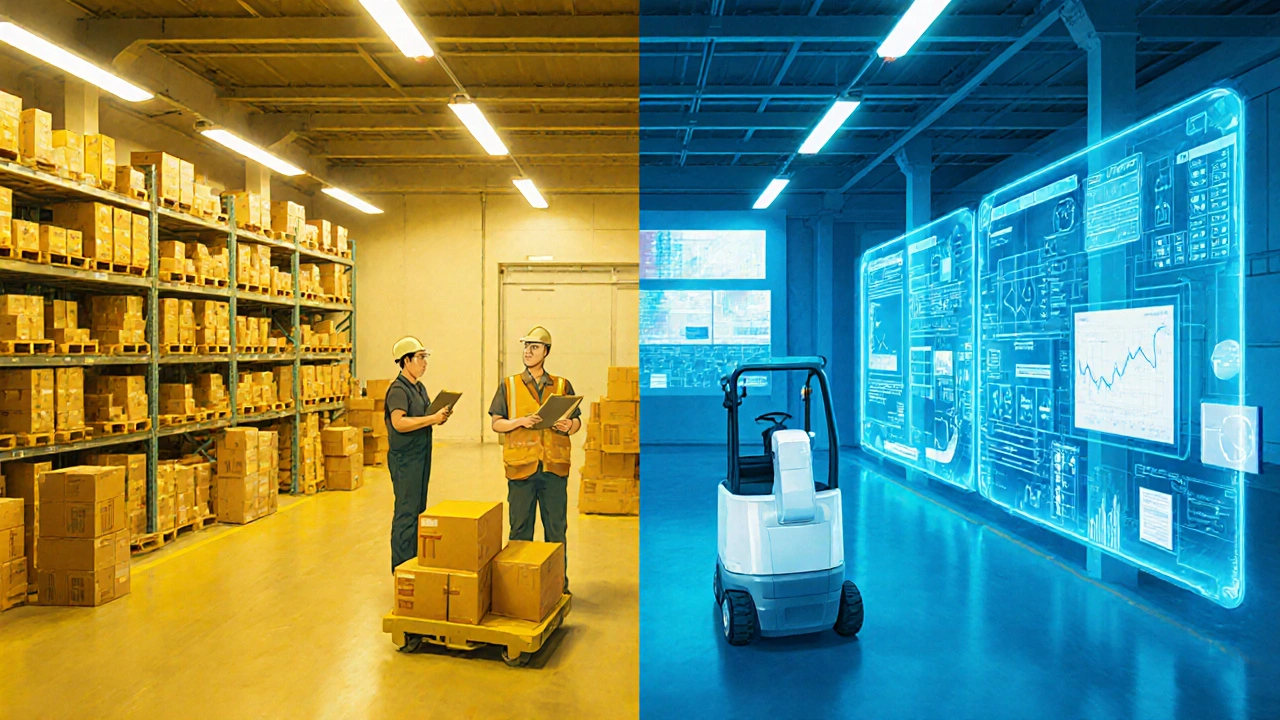

Think about the last time you ordered something online. That package didn’t just appear out of nowhere. It came from a warehouse-probably one that’s running like a well-oiled machine without a single person walking up and down aisles with a clipboard. That’s the power of a smart warehouse management system. It’s not just software. It’s a full digital nervous system that connects robots, sensors, scanners, and people to keep inventory moving accurately and fast.

What Exactly Is a Smart Warehouse Management System?

A smart warehouse management system (WMS) is a digital platform that controls and optimizes daily warehouse operations using real-time data, automation, and artificial intelligence. Unlike old-school systems that just logged what came in and out, modern smart WMS tools predict what’s needed, tell workers where to go, and even adjust workflows based on live demand.

It’s not magic-it’s technology working together. Sensors track pallet locations. Barcode scanners confirm shipments. RFID tags monitor high-value items. AI forecasts stock levels. All of this feeds into one central dashboard that warehouse managers can access from any device.

Companies using smart WMS report up to 40% fewer picking errors, 25% faster order fulfillment, and 30% less wasted space. That’s not theory. It’s what’s happening right now in warehouses across New Zealand, the U.S., and Germany.

How Does a Smart WMS Work? The Core Components

A smart warehouse management system doesn’t run on one tool. It’s made of five key parts that talk to each other:

- Inventory tracking - Every item gets a digital ID. Whether it’s a single screw or a pallet of coffee beans, the system knows its exact location, quantity, and condition. No more guessing where the last box of printer paper went.

- Real-time data capture - Scanners, RFID readers, and IoT sensors update the system the second something moves. A forklift picks up a box? The system knows. A worker scans a label? The inventory updates instantly.

- Automated task routing - Instead of assigning random tasks, the system tells workers the most efficient path. Need to pick 12 items for five orders? The WMS shows you the shortest route-cutting walking time by up to 50%.

- Integration with other systems - A smart WMS doesn’t live in a bubble. It connects to your e-commerce platform, ERP system, transportation management software, and even your supplier portals. When a customer buys a product online, the WMS automatically reserves it, picks it, and schedules a shipment.

- AI-powered analytics - The system learns from patterns. If sales of winter coats spike every April in Auckland, it starts pre-positioning stock near the port before the season hits. It predicts stockouts before they happen.

These pieces don’t just make things faster-they make them smarter. For example, a warehouse in Hamilton started using a smart WMS with AI forecasting. Within three months, they reduced overstock by 22% and cut emergency rush orders by 60%.

Smart vs. Traditional Warehouse Systems

Old warehouse systems were like paper ledgers with a computer screen. They recorded what happened-but didn’t help you avoid mistakes or plan ahead.

Here’s how they compare:

| Feature | Smart WMS | Traditional System |

|---|---|---|

| Inventory Accuracy | 99.5%+ with real-time tracking | 85-92% with manual counts |

| Picking Speed | 25-40% faster with optimized routes | Slower, based on memory or paper lists |

| Space Utilization | Up to 30% more efficient with dynamic slotting | Fixed locations, often underused |

| Scalability | Easily handles spikes in demand | Struggles during peak seasons |

| Reporting | Live dashboards, predictive insights | Manual reports, delayed data |

One Auckland-based electronics distributor switched from a legacy system to a cloud-based smart WMS. Before, they had to shut down for three days each quarter to do a full physical inventory. Now, they do spot checks once a month-and their stock accuracy is better than ever.

Who Uses Smart WMS? Real-World Examples

You might think smart WMS is only for big companies. But that’s not true anymore.

- Small e-commerce brands use affordable SaaS WMS tools to compete with Amazon. One Wellington-based seller of organic skincare products went from 200 to 1,200 orders a week without hiring extra staff.

- Pharmaceutical distributors rely on smart WMS for traceability. Each medicine bottle has a unique code. If there’s a recall, the system finds every single unit in under five minutes.

- Food and beverage warehouses use temperature sensors and expiry date alerts. Expired stock gets flagged before it’s picked. Spoilage dropped by 18% at a Christchurch dairy warehouse after implementation.

- Third-party logistics (3PL) providers manage dozens of clients from one platform. Each client’s inventory, branding, and rules are kept separate-but all tracked in real time.

Even mid-sized manufacturers are adopting smart WMS to cut delays. A Tauranga-based furniture maker used to wait 48 hours to confirm if they had enough legs for a batch of chairs. Now, the system alerts them when stock dips below 100-and auto-orders replacements from the supplier.

What You Need to Get Started

Jumping into a smart WMS isn’t about buying the fanciest software. It’s about matching your needs.

Start with these three questions:

- How many SKUs do you handle? Under 5,000? You can start with a basic cloud WMS. Over 50,000? You’ll need advanced features like wave picking and multi-location support.

- What’s your peak season like? If you get 3x more orders in December, make sure the system scales easily. Look for cloud-based platforms that add capacity on demand.

- What systems do you already use? Does your e-commerce site run on Shopify? Your accounting on Xero? Make sure the WMS integrates natively. Avoid custom coding-it’s expensive and breaks often.

Most small to medium businesses start with a cloud-based WMS like Fishbowl, Zoho Inventory, or NetSuite. These cost between $100 and $500 a month, depending on features. No big upfront hardware costs. Setup usually takes 2-6 weeks.

Common Mistakes to Avoid

Many companies think buying software is the hard part. It’s not. The real challenge is change.

- Skipping staff training - Workers used to walking aisles with clipboards will resist scanning every item. Show them how it saves time. Run practice drills. Reward accuracy.

- Ignoring data quality - If your initial inventory count is wrong, the system will keep making bad decisions. Clean your data before you go live.

- Choosing the wrong vendor - Don’t pick based on price alone. Look for vendors with experience in your industry. Ask for case studies. Talk to current users.

- Trying to automate everything at once - Start with picking and inventory. Add robotics or AI forecasting later. Don’t overwhelm your team.

One Bay of Plenty warehouse spent $80,000 on a system that didn’t integrate with their existing ERP. They had to manually re-enter data twice a day. They wasted six months and $20,000 more fixing it. Learn from that.

What’s Next for Smart Warehousing?

The next wave is even smarter. Warehouses are starting to use:

- Autonomous mobile robots (AMRs) - Self-driving carts that follow digital maps to fetch items. No wires, no magnets. Just AI and sensors.

- Digital twins - A virtual copy of your warehouse. Test changes in the simulation before you make them in real life.

- Computer vision - Cameras that recognize items without barcodes. Just point a camera at a box, and the system knows what it is.

By 2027, Gartner predicts over 60% of mid-sized warehouses will use AI-driven WMS tools. The ones that don’t will struggle to keep up on speed, cost, and accuracy.

Smart warehouse management isn’t a luxury anymore. It’s the baseline for survival.

Is a smart warehouse management system only for large companies?

No. Cloud-based smart WMS platforms now cost as little as $100 a month and require no heavy hardware. Small e-commerce businesses, local distributors, and even single-location retailers use them to compete with bigger players. The key is starting small-focus on inventory accuracy and picking efficiency first.

Can a smart WMS integrate with my existing e-commerce platform?

Yes, most modern WMS tools connect directly with Shopify, WooCommerce, Magento, and Amazon Seller Central. When a customer places an order, the WMS automatically creates a picking task, reserves stock, and updates tracking info. No manual entry needed. Always check for native integrations before buying.

How long does it take to implement a smart WMS?

For small to medium warehouses, implementation usually takes 2 to 6 weeks. This includes data cleanup, staff training, and system testing. Larger warehouses with complex workflows might need 3-6 months. The biggest delay isn’t software-it’s getting your team on board and cleaning up old inventory records.

Do I need robots or special hardware to use a smart WMS?

No. You can start with just barcode scanners, tablets, and cloud software. Many businesses see major improvements without any robots. Hardware like AMRs or automated storage systems come later, once you’ve optimized your processes and need more speed. Start with software, then add hardware as needed.

What’s the biggest benefit of a smart WMS?

The biggest benefit is accuracy-combined with speed. Smart WMS reduces picking errors from 5-10% down to under 0.5%. It cuts order fulfillment time by a third. And because it knows exactly where every item is, you use less space and avoid over-ordering. That means lower costs, happier customers, and more room to grow.

Next Steps for Your Warehouse

If you’re thinking about upgrading, start here:

- Take a full inventory count. Fix any mismatches.

- List your top three pain points: slow picking? Stockouts? Wrong shipments?

- Try a free trial of a cloud WMS like Zoho Inventory or Fishbowl.

- Ask your current software provider if they offer a smart upgrade.

- Talk to one warehouse manager in your industry who already uses it.

You don’t need to go all-in tomorrow. But if you’re still using paper lists or spreadsheets to track inventory, you’re already falling behind. The smart warehouse isn’t the future. It’s the present-and it’s here to stay.