Coca-Cola, a brand synonymous with refreshment across the globe, owes much of its seamless product availability to the intricate tapestry of its logistics and warehouse operations. As one might expect from a company of such scale, their warehousing strategy is no mere afterthought but rather a backbone of their supply chain.

From state-of-the-art distribution centers to strategically located facilities, Coca-Cola's warehouses do more than just store bottles and cans. They are hubs of activity where technology, innovation, and sustainability walk hand in hand to support the brand's promise to its consumers. But what exactly goes on behind those massive doors? How does Coca-Cola ensure your favorite drink is always within reach?

In this exploration, we'll delve into how Coca-Cola uses these warehouses, the types they operate, and the cutting-edge innovations they employ to keep their operations not only smooth but also environmentally friendly. Join us as we navigate the corridors of one of the world's most famous supply chains, right from the factory floor to your local store shelf.

- The Role of Warehouses in Coca-Cola's Supply Chain

- Types of Warehouses and Their Functions

- Logistic Innovations and Technology Utilization

- Sustainability Practices in Warehousing

- Challenges Faced in Coca-Cola's Warehousing

- Future Trends in Coca-Cola's Logistics Strategy

The Role of Warehouses in Coca-Cola's Supply Chain

In the vast and bustling world of global beverages, Coca-Cola stands out as a titan, not just because of its popular products but because of its meticulous logistics and warehousing strategy. At the heart of Coca-Cola's supply chain are its warehouses, which function as critical nodes in ensuring that their drinks reach every corner of the globe efficiently. These warehouses are not just places of storage; they are dynamic spaces where logistical magic happens daily. Their role begins right after the production of the beverages and extends until the final product is transported to local markets, ready to be consumed by enthusiastic customers. A significant aspect of these warehouses is how seamlessly they integrate with Coca-Cola's distribution strategies, ensuring that delivery schedules are met without a hitch, even as market demands fluctuate.

Coca-Cola employs a strategic network of warehouses, each designed for specific purposes, whether it's for holding raw materials or finished products. These facilities are often located in proximity to production plants to minimize transportation costs and times. By doing so, Coca-Cola can swiftly respond to market demands, especially during peak seasons. Inside, sophisticated management systems govern everything from inventory tracking to the optimal storage conditions necessary for maintaining product quality. It's within these walls that technology and logistics intertwine, and every aspect of the warehouse's operation is geared towards reducing delays and optimizing the flow of goods within the supply chain.

While traditional warehousing is part of the equation, Coca-Cola has not shied away from innovation. Employing advanced logistics technologies, such as warehouse management systems (WMS) and automated guided vehicles (AGVs), enables them to maintain a high level of operational efficiency. This approach allows real-time tracking of inventory levels and dynamic adjustment of storage spaces, thereby accommodating shifts in demand. It's a testament to how Coca-Cola remains committed to revolutionizing its logistics practices, setting industry benchmarks. To underscore this, an industry expert once noted,

"Coca-Cola's ability to innovate within its supply chain is largely due to how it leverages technology within its vast warehousing network."

The commitment to sustainability is also evident in Coca-Cola's warehousing practices. As a part of their global responsibility, they have incorporated eco-friendly designs in newer facilities, such as green roofs and energy-efficient lighting systems, which reduce carbon footprints. This initiative doesn't merely benefit the environment but also translates into cost savings and enhances the company's reputation as an environmentally conscious entity. Warehousing thus becomes a strategic asset in Coca-Cola's supply chain, where every aspect is optimized not just for profit, but for people and the planet.

In today's fluctuating market, adaptability is crucial. Coca-Cola's approach to warehousing exemplifies this as they leverage data analytics to predict demand patterns and adjust their logistics operations accordingly. This proactive strategy allows them to maintain product availability, ensuring that their beverages are consistently on store shelves, regardless of external conditions. It's this ability to anticipate and adjust that showcases the importance of warehouses within Coca-Cola's supply chain, ensuring their beverages continue to be enjoyed worldwide.

Types of Warehouses and Their Functions

When delving into the logistics world of Coca-Cola, it becomes evident that their warehouse operations are both diverse and intricate. The types of warehouses they employ aren't just about housing products; each type serves a unique function tailored to meet the complex demands of their supply chain. One of the primary types of warehouses in their arsenal is the distribution center. These centers act as the nerve centers where products are received from production plants, sorted, packaged, and finally distributed to retail locations. Notably, these centers are strategically placed to ensure products can move swiftly to various market regions.

Beyond distribution centers, Coca-Cola also utilizes refrigerated warehouses. These facilities are crucial for storage of products that require temperature control, ensuring the beverages maintain their quality throughout transit. The emphasis on refrigerated warehousing highlights Coca-Cola's commitment to preserving product freshness and taste integrity. Equally vital are the raw material warehouses, which store ingredients like concentrate, sugar, and packaging materials. These are pivotal in ensuring a steady feed of materials for the production lines, reinforcing Coca-Cola's ability to meet production timelines efficiently.

Moreover, Coca-Cola's regional warehouses play a critical role. These are typically smaller and cater to specific geographic areas, ensuring quick response and adjustment to local market demands. This local approach allows for streamlined operations, helping Coca-Cola balance global consistency with local preferences. In an intriguing statement, a logistics expert once noted, "Warehouse strategy isn't just about storage; it's about anticipation and adaptation."

In the realm of data-driven decision-making, Coca-Cola incorporates the use of smart warehouses. These modern facilities leverage advanced technologies like IoT and AI. Through automation, they increase accuracy in inventory management and improve the speed of order processing. This tech-forward approach reflects a trend where tradition meets innovation, allowing Coca-Cola to maintain an edge in the fast-paced logistics landscape. The company's commitment to integrating technology in logistics underscores its drive toward efficiency and sustainability.

Lastly, in consideration of the environmental impact, Coca-Cola has been exploring green warehouses. These facilities are designed with eco-friendly features such as solar panels, energy-efficient lighting, and rainwater harvesting systems. By adopting sustainable practices within their warehouses, Coca-Cola not only reduces its carbon footprint but also sets a benchmark for others in the industry to follow.

Logistic Innovations and Technology Utilization

Coca-Cola's extensive global reach is supported by a deeply integrated logistics system, which hinges significantly on cutting-edge innovations and technology. As a titan in the beverage industry, Coca-Cola deploys advanced technological solutions to streamline and optimize their supply chain operations. From automated warehouses to AI-driven analytics, these innovations are designed to elevate efficiency. It is not merely about moving products from point A to B, but about creating a seamless network that anticipates and reacts to market dynamics. By incorporating AI, Coca-Cola can predict demand patterns, adjust inventory levels, and minimize waste, ensuring their *supply chain* responds adeptly to fluctuations.

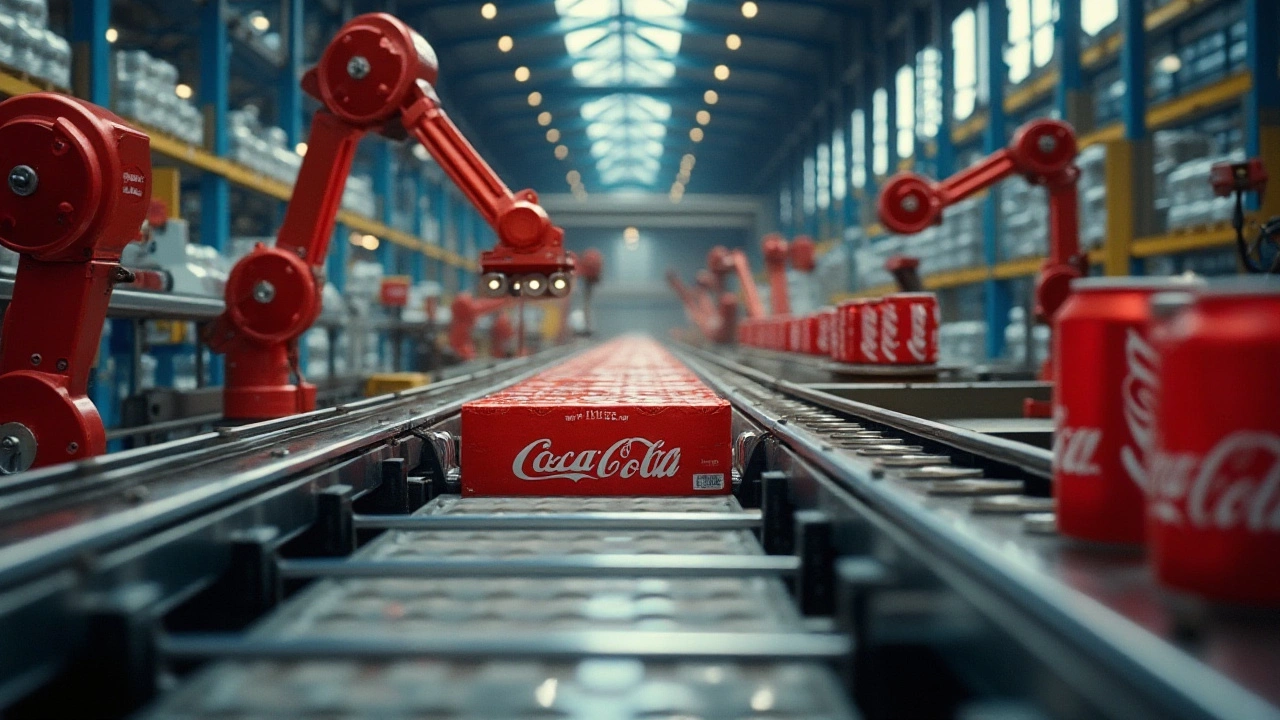

One of the most remarkable advancements in Coca-Cola's logistics is their use of robotic automation within their warehouses. These robotics systems can work tirelessly, handling repetitive tasks like sorting and packing with precision and speed that surpass human capabilities. This not only accelerates the process but also reduces human error, offering a more reliable and robust supply chain. Additionally, Coca-Cola integrates IoT (Internet of Things) devices, which provide real-time data, enabling managers to monitor and adjust operations from anywhere. This real-time insight ensures quick responses to any disruptions, maintaining the flow of their beloved beverages to markets worldwide.

An example of Coca-Cola's commitment to technological advancement is their collaboration with Agility Robotics, a partnership aimed at exploring new avenues in warehouse automation. They also engage with various start-ups and tech labs to stay at the forefront of logistics innovation. By investing in startups, Coca-Cola often holds a front-row seat to the latest technological breakthroughs, enabling them to integrate cutting-edge solutions more rapidly than competitors. According to a statement by Muhtar Kent, former CEO of Coca-Cola,

"Continuous innovation is the heart of sustaining a competitive supply chain. By fostering collaborations, we open doors to pioneering solutions that redefine industry standards."

To further empower their logistics, Coca-Cola places stock in sustainable practices. They employ electric delivery vehicles and optimize routes using AI, reducing their carbon footprint significantly. In some facilities, solar panels power operations, aligning with their commitment to environmental stewardship. This sustainable approach not only curbs emissions but also reduces operational costs, allowing Coca-Cola to invest in more innovation. These practices showcase how Coca-Cola marries technological prowess with sustainability, ensuring they remain an industry leader not only in sales but also in responsible corporate practices. As we look to the future, these innovations underscore Coca-Cola’s drive to not just keep up with the times, but to actively shape the future of logistics and supply chain management.

Sustainability Practices in Warehousing

When it comes to sustainability, Coca-Cola is determined to lead by example, particularly in their extensive network of warehouses. These facilities are more than just stockyards for the company's products; they are proving grounds for innovative approaches aimed at reducing the carbon footprint. Coca-Cola has made significant strides in ensuring that their logistics operations align with their overarching environmental goals. One key approach is the switch to renewable energy across many of their warehouses, which not only cuts down on greenhouse gas emissions but also sets a precedent for other companies in the industry. Solar panels adorn rooftops, harnessing the power of the sun to fuel daily operations, while energy-efficient lighting and equipment work to minimize energy consumption further.

Additionally, waste reduction is a major focus in Coca-Cola's sustainability agenda. Warehouses are equipped with advanced recycling systems that manage everything from plastic and metals to the even more challenging waste streams of packaging materials. This meticulous sorting and recycling process is vital in achieving the company’s goal of creating a 'World Without Waste'. In 2023, Coca-Cola reported that these initiatives allowed them to recover and recycle around 60% of the packaging sent to market, a significant achievement that continues to drive their sustainability narrative.

Not stopping at energy and waste, Coca-Cola has also implemented a water stewardship program, which is especially relevant given the increasing pressures on global water resources. The warehouses prioritize water reuse through cutting-edge treatment systems. In numerous locations, they capture rainwater and recycle process water, contributing not just to conservation efforts but also reinforcing their commitment to efficient resource use. This initiative is particularly impactful in regions where water scarcity is a pressing issue.

Moreover, optimization of logistic operations plays a crucial role in their sustainability strategy. By employing sophisticated computer modeling and data analytics, Coca-Cola optimizes the routes and loads of their delivery fleets. This not only cuts fuel usage but also reduces emissions, forming part of a much larger logistical puzzle. It’s remarkable to note how interconnected their operations are, weaving sustainability into the very fabric of their supply systems. As noted by James Quincey, Coca-Cola's CEO,

"Our responsibility extends beyond our products and into how we bring them to market, impacting communities positively along the way."

To shed some light on the effectiveness of these programs, it's worth looking at some numbers. A 2024 sustainability report highlighted that the combination of these cutting-edge practices resulted in a 25% reduction in operational emissions within the previous five years. The tables are turning, quite literally, as Coca-Cola transforms traditional warehousing into green hubs of efficiency. And this transformation is not only about meeting current regulatory requirements—it’s about setting new standards in a continuously evolving landscape.

In essence, Coca-Cola's commitment to sustainability in warehousing reflects a broader narrative of responsibility and innovation. From renewable energy use to intricate recycling systems and optimized logistics, their embracing of green practices is as bold as their flavors are recognizable. These efforts not only enhance Coca-Cola’s brand as a leader in sustainable practices but also inspire many across industries to rethink their strategies. It's a dynamic process, one that continues to evolve, proving that even the most established giants can change course towards a brighter, greener future.

Challenges Faced in Coca-Cola's Warehousing

Coca-Cola, with its vast network that spans the globe, encounters unique challenges within its warehousing operations. Managing such an extensive supply chain comes with its fair share of hurdles that demand constant attention and innovative solutions. Among these challenges, maintaining efficiency while meeting high consumer expectations remains paramount. These warehouses are integral in ensuring that the vast array of Coca-Cola products are adequately stored and distributed, from sparkling beverages to juices, in a manner that preserves quality and freshness.

A significant challenge for Coca-Cola is geographic diversity. The company operates in over 200 countries, which means dealing with a wide range of local regulations, cultural differences, and logistical limitations. In regions with limited infrastructure, setting up efficient warehousing systems becomes particularly taxing. The task requires meticulous planning and adaptation, as each location's warehousing requirements can differ vastly based on climate, demand, and transportation links. Such regional variability often requires Coca-Cola to innovate and customize storage solutions to suit local needs.

Technology integration presents another layer of complexity. Although advanced technologies can streamline operations, implementing them across numerous facilities is no small feat. Ensuring uniformity in digital systems while allowing for localized adjustments is crucial yet challenging. Moreover, as Coca-Cola moves towards more sustainable operations, integrating eco-friendly technologies into their warehouse facilities demands further investment and recalibration of their existing processes. It's a balance between staying ahead in modern logistics and ensuring that all processes align with global sustainability goals.

Warehouses are also pivotal in handling peak demand fluctuations. Special occasions like the Super Bowl or national holidays can spike demand unpredictably. Coca-Cola must build flexibility into their warehousing logistics to cater to these spikes without compromising their baseline operations. This flexibility often involves tight coordination with transport networks, manufacturers, and retailers to ensure a seamless increase in distribution speed and volume. According to an industry expert, optimizing for such variability requires a complex dance of predictive analytics and efficient resource allocation.

Coca-Cola's strategic operations emphasize the importance of agility and innovation to overcome warehousing challenges presented by global demand diversity.

Moreover, labor considerations represent a non-trivial challenge. Staffing warehouses appropriately, especially in peak times, while maintaining safety and adherence to labor laws, is crucial. Training staff consistently across diverse regions can be cumbersome yet necessary to maintain operational excellence. The human element is where Coca-Cola invests significantly, understanding that their workforce is the core asset when bridging logistical gaps. They strive for a model that harmonizes technology and human expertise, creating a workforce that is not only skilled but adaptable to changes.

The company's dedication to sustainability adds another layer of challenge in warehousing. Coca-Cola has pledged to reduce its carbon footprint substantially, which means rethinking how warehouses consume and manage resources. They have been working towards energy-efficient storage solutions, including facilities powered by renewable energy sources. This endeavor is both a challenge and an opportunity for the company to lead by example in the pursuit of a more sustainable future.

Coca-Cola continuously adapts to meet these challenges head-on. They view obstacles not just as barriers but as catalysts for further ingenuity and leadership in the logistics world. While the hurdles are formidable, their proactive approach and commitment to innovation continue to set them apart in the competitive landscape.

Future Trends in Coca-Cola's Logistics Strategy

The future of logistics at Coca-Cola is painted with hues of innovation, technology, and sustainability. Being at the forefront of the beverage industry, Coca-Cola is not just rolling with the changes but leading the way toward smarter logistics solutions. As we look ahead, one of the key trends is the integration of artificial intelligence and machine learning into their supply chain. These technologies are set to revolutionize forecasting accuracy, giving them the ability to anticipate demand with unprecedented precision and reducing waste in the process.

The digitization of warehouse management systems is also on the horizon for Coca-Cola, propelling them towards a more efficient, connected, and automated supply chain. This shift is anticipated to improve real-time data sharing and tracking, greatly enhancing shipment tracking and inventory management. The use of smart sensors and IoT devices to monitor and optimize energy use in warehouses aligns with the company's push towards reducing its carbon footprint.

Additionally, Coca-Cola is embracing the concept of green logistics. Their focus on reducing energy consumption and deploying greener methods of transportation is more than just a trend; it’s a necessity. The utilization of electric delivery vehicles and innovations in eco-friendly packaging are part of Coca-Cola's commitment to sustainability. According to studies, logistics operations contribute significantly to a company's carbon output, and Coca Cola’s endeavor to minimize this impact is leading to a wave of sustainability efforts within the industry.

"As a business, we continue to focus on enhancing our energy efficiency programs and exploring new technologies that drive our sustainability commitments," said Bea Perez, Chief Communications, Sustainability and Strategic Partnerships Officer at Coca-Cola.

The future also sees Coca-Cola investing in collaborative robots—or cobots—that assist with warehouse sorting and packing tasks. This not only increases efficiency but also addresses labor shortages. As these cobots take care of repetitive tasks, human workers can focus on more strategic roles which require creative thinking. Another area to watch is the potential of blockchain technology in improving Coca-Cola's supply chain transparency. With blockchain, the ability to trace the lifecycle of each product—from sourcing to sale—could greatly increase operational transparency and security.

The logistics landscape is ever-evolving, and Coca-Cola’s adaptability to trends is key to maintaining its legacy. By anticipating challenges and being proactive about implementing cutting-edge solutions, Coca-Cola continues to set the bar for logistics strategies in the beverage industry.