Warehouse Management System (WMS): What It Is and How to Pick the Right One

Got a warehouse and feel like you’re juggling pallets, orders, and staff all at once? A Warehouse Management System, or WMS, is the digital assistant that keeps everything in line. It tracks inventory, tells workers where to pick items, and helps you ship orders without missing a beat. In short, a good WMS turns chaos into a smooth flow, saves time, and cuts costly mistakes.

Most businesses start with a simple spreadsheet, but as soon as you have more SKUs or need faster shipping, that spreadsheet becomes a nightmare. That’s where a dedicated WMS steps in – it automates the grunt work, gives you real‑time visibility, and integrates with other tools like transport management (TMS) or ERP systems. If you’re already reading posts like "What Software Is Used in Supply Chain Management?" you’ll see why a WMS is a core piece of the supply‑chain puzzle.

Four Main Types of Warehouse Management Systems

Not every WMS fits every warehouse. The market splits into four basic models, each built for a different need:

- Standalone WMS: A single‑purpose tool that focuses on inventory tracking and order picking. Ideal for small‑to‑medium warehouses that don’t need deep integration.

- Cloud‑based WMS: Hosted online, easy to scale, and usually subscription‑priced. Great if you want low upfront costs and regular updates.

- Supply‑chain suite WMS: Part of a larger ERP or SCM platform. It talks to finance, sales, and shipping modules, giving a 360° view of operations.

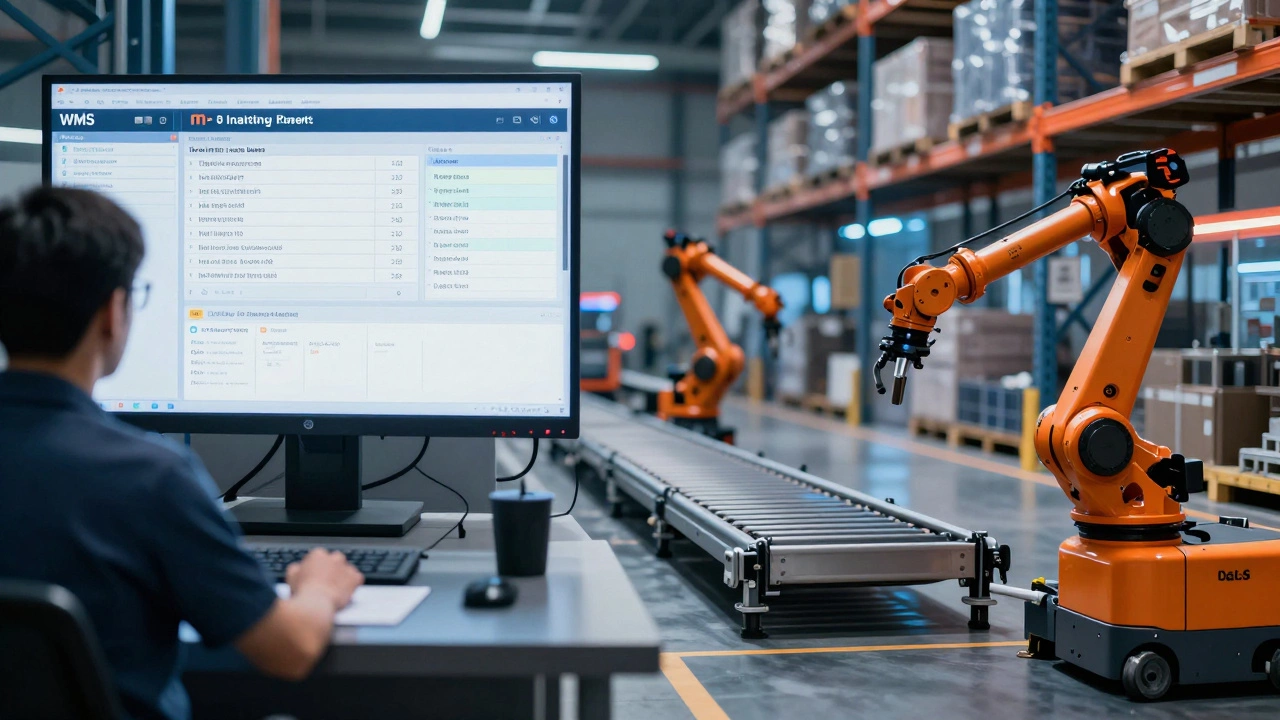

- Advanced automation WMS: Works with robots, conveyors, and IoT sensors. Best for high‑volume facilities looking to push efficiency to the limit.

Our own "Types of Warehouse Management Systems: Guide to the Four Main WMS Models" breaks down each option with real‑world examples, so you can match a model to your budget and growth plans.

How to Choose and Implement a WMS That Works for You

Choosing a WMS isn’t just about picking the flashiest interface. Follow these practical steps:

- Map your current processes. Write down how you receive stock, store it, pick orders, and ship out. Knowing the flow helps you spot gaps a WMS can fill.

- Set clear goals. Do you need faster order turnaround, better accuracy, or the ability to manage multiple sites? Prioritize those goals when scoring software.

- Test with real data. Most vendors offer a sandbox or trial. Load a few days of actual inventory and see how the system handles it. Watch for bottlenecks.

- Check integration points. Make sure the WMS can talk to your existing ERP, accounting, or e‑commerce platform. Seamless data flow saves manual entry.

- Plan the rollout. Start with one warehouse or one product line. Train staff, collect feedback, and adjust before going full scale.

Implementation often trips up teams that skip training. Keep it simple: run short hands‑on sessions, create cheat sheets, and assign a “WMS champion” on the floor who can answer questions in real time.

Once live, watch key metrics like order‑to‑ship time, pick accuracy, and inventory turnover. These numbers tell you whether the system is delivering the promised ROI.

In a nutshell, a Warehouse Management System is the backbone that turns a crowded floor into a well‑orchestrated operation. Whether you pick a cloud‑based starter or an advanced automation suite, the right WMS will keep inventory visible, workers efficient, and customers happy. Ready to upgrade? Start by listing your biggest pain points and match them to the four WMS types – you’ll be surprised how quickly the right solution shows up.

January 12, 2026

Evelyn Wescott

0 Comments

Learn the four main types of warehouse management systems (WMS)-standalone, ERP-integrated, supply chain-connected, and cloud-based-and which one fits your operation best in 2026.

December 28, 2025

Evelyn Wescott

0 Comments

Learn how to choose a warehouse management system that cuts errors, saves time, and scales with your business. Avoid common mistakes and find the right fit for your operation in 2025.

December 4, 2025

Evelyn Wescott

0 Comments

SAP powers modern warehouses by tracking inventory in real time, optimizing picking routes, and integrating with shipping and ERP systems. Learn how it reduces errors, cuts labor waste, and scales with your business.

December 1, 2025

Evelyn Wescott

0 Comments

A warehouse management system (WMS) tracks inventory and orders, while a warehouse control system (WCS) manages automated equipment. Learn how they work together-and when you need one or both.

December 1, 2025

Evelyn Wescott

0 Comments

A Warehouse Management System (WMS) is software that tracks inventory, directs warehouse workers, and speeds up order fulfillment. Learn how WMS works, who uses it, and why it's essential for modern logistics.

June 28, 2025

Evelyn Wescott

0 Comments

Explore if Oracle functions as a WMS, dissecting its features, real-world uses, and how it stands among warehouse management solutions. Get clarity on what Oracle offers for logistics.

March 25, 2025

Evelyn Wescott

0 Comments

Discovering the right software for warehouses can significantly enhance efficiency by streamlining inventory management, optimizing space, and improving operational flow. This article explores popular software solutions that cater to various warehouse needs, from Warehouse Management Systems to Inventory Control Software. Dive into practical tips and insights on choosing the best tools for your warehouse. Learn how advanced analytics and automation are paving the way for smarter warehouse operations.

January 24, 2025

Evelyn Wescott

0 Comments

Warehouse Management Systems (WMS) are essential tools for businesses looking to optimize their supply chain operations. Suitable for enterprises of various sizes, WMS enhances efficiency by streamlining inventory management, order processing, and logistics. Companies from different industries like retail, manufacturing, and e-commerce widely adopt these systems to maintain competitive advantage. This article explores the diverse users of WMS, ranging from small warehouses to large multinational corporations, and highlights the benefits they experience.