Warehouse Automation Made Simple

Running a warehouse by hand feels like juggling too many balls at once. One misplaced box, a slow picker, or a broken conveyor can hold up an entire delivery chain. That’s why more UK businesses are turning to automation. With the right tools, you can move stock faster, lower labor costs, and keep customers happy. Below we break down the basics, so you can decide what fits your operation without getting lost in tech jargon.

Why automate your warehouse?

First off, automation cuts down on human error. Scanners, barcode readers, and RFID tags catch mistakes before a pallet leaves the dock. Fewer errors mean fewer returns and less time spent chasing down the wrong order. Second, machines work around the clock. A conveyor belt or a robotic arm doesn’t need coffee breaks, so you can keep picking and packing even during off‑peak hours. Third, data from automated systems gives you real‑time visibility. You can see which items are running low, which zones are busiest, and where bottlenecks form. This insight lets you plan better, reorder smarter, and avoid costly stock‑outs.

Key tools to get started

Barcode and RFID scanners. Start with handheld scanners that link to a cloud‑based inventory system. They’re cheap, easy to train on, and instantly improve accuracy. If you have higher volume, upgrade to fixed RFID readers at entry and exit points – they read multiple tags at once, speeding up bulk moves.

Conveyor belts and sorting systems. A simple belt can move pallets from receiving to storage without manual lifting. For e‑commerce spikes, a sortation carousel routes parcels to the right packing lane in seconds. These systems pay for themselves fast as labor hours shrink.

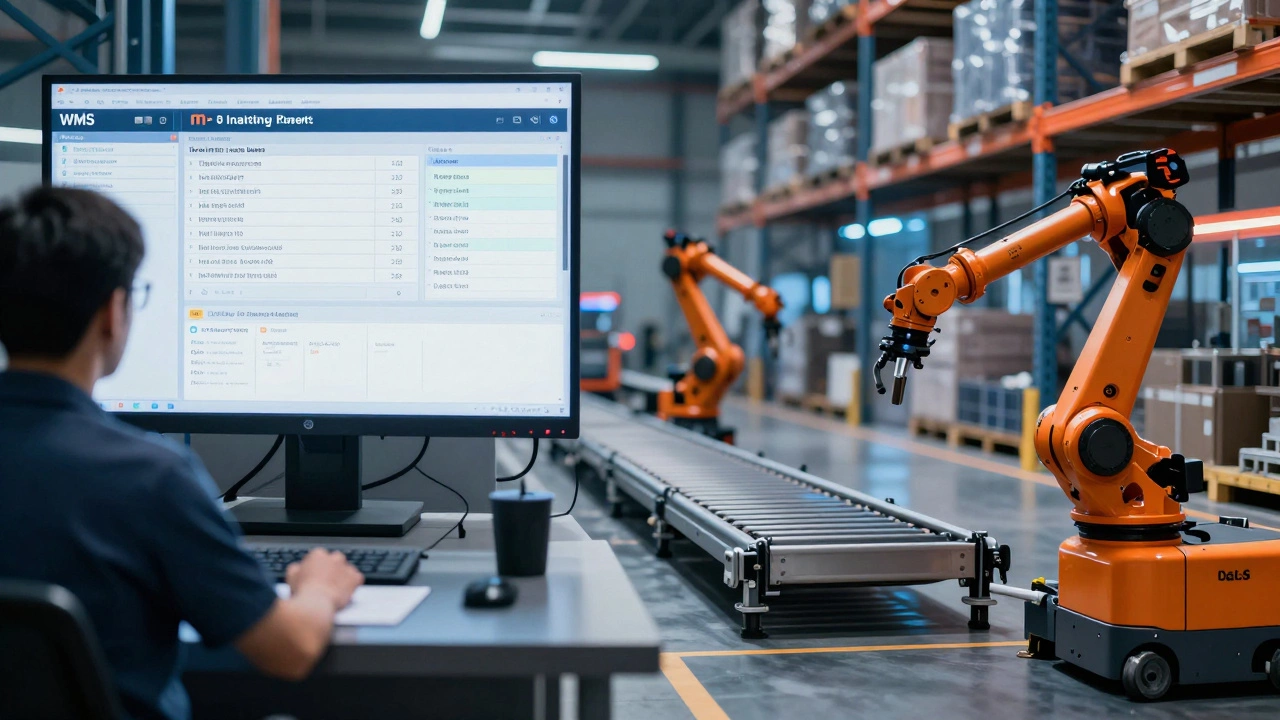

Warehouse Management Software (WMS). A good WMS ties together scanners, conveyors, and your transport partners. It shows you where every SKU lives, schedules pick routes, and can even suggest the best storage slot based on demand. Look for a solution that integrates with your existing ERP or logistics platform – Dex Removals, for example, plugs into most WMS tools to streamline the final delivery step.

Robotic pickers. If space is tight and orders are complex, collaborative robots (cobots) can fetch items from shelves and hand them to human packers. They’re safe to work alongside people and can be programmed for different product sizes. Start with a single robot in a high‑traffic aisle and expand as you see time savings.

Implementing automation doesn’t have to be an all‑or‑nothing project. Begin with the low‑cost items – barcodes, a basic WMS, and a short conveyor line – then layer on more advanced tools like robotics. Keep your staff involved; training them on new equipment reduces pushback and uncovers practical tweaks.

At Dex Removals & Logistics Services, we’ve helped dozens of UK firms upgrade their warehouses. Our team can assess your current flow, recommend the right tech, and handle the installation so you stay on schedule. Whether you need a quick pallet‑move solution or a fully automated fulfillment center, we’ve got the expertise to keep your goods moving.

Ready to see how automation can boost your bottom line? Reach out for a free warehouse audit and start turning those bottlenecks into smooth, fast lanes.

January 26, 2026

Evelyn Wescott

0 Comments

Logistics profitability in 2026 isn't about fleet size-it's about software. Companies using route optimization and warehouse automation are hitting 8-15% net margins. Manual operations barely break even.

January 12, 2026

Evelyn Wescott

0 Comments

Learn the four main types of warehouse management systems (WMS)-standalone, ERP-integrated, supply chain-connected, and cloud-based-and which one fits your operation best in 2026.

December 1, 2025

Evelyn Wescott

0 Comments

A warehouse management system (WMS) tracks inventory and orders, while a warehouse control system (WCS) manages automated equipment. Learn how they work together-and when you need one or both.

November 8, 2025

Evelyn Wescott

0 Comments

A smart warehouse management system uses real-time data, automation, and AI to track inventory, optimize picking, and reduce errors. Learn how it works, who uses it, and why it’s essential for modern logistics.

October 18, 2025

Evelyn Wescott

0 Comments

Learn what a logistics management system is, its core modules, tech enablers, benefits, and how to choose and implement the right solution for your supply chain.

August 5, 2025

Evelyn Wescott

0 Comments

Explore the four types of warehouse management systems, understand how each fits different businesses, and learn tips for picking the right WMS.

July 5, 2025

Evelyn Wescott

0 Comments

Discover the nuts and bolts of logistics software—how it manages supply chains, cuts costs, automates warehouses, and boosts delivery in real time.

May 2, 2025

Evelyn Wescott

0 Comments

Ever wondered why Amazon’s packages get to your door so quickly? This article unpacks the smart logistics software powering their speedy deliveries. Get the scoop on real-time tracking, smart warehouse robots, and how their route optimization saves time and money. You'll learn useful facts and tips for improving your own logistics setup. Discover what actually sets Amazon apart in the logistics game.

April 29, 2025

Evelyn Wescott

0 Comments

Modern warehousing isn’t just about storage – it’s become a tech powerhouse. This article breaks down the latest technologies shaking up the warehouse world. From robots to AI, discover what’s making operations faster, smarter, and more accurate. You’ll also pick up practical tips and surprising facts about how these innovations change everyday warehouse work. Dive in to see what tools are driving warehouse efficiency in 2025.