Warehouse Control System: What It Is and How It Powers Modern Logistics

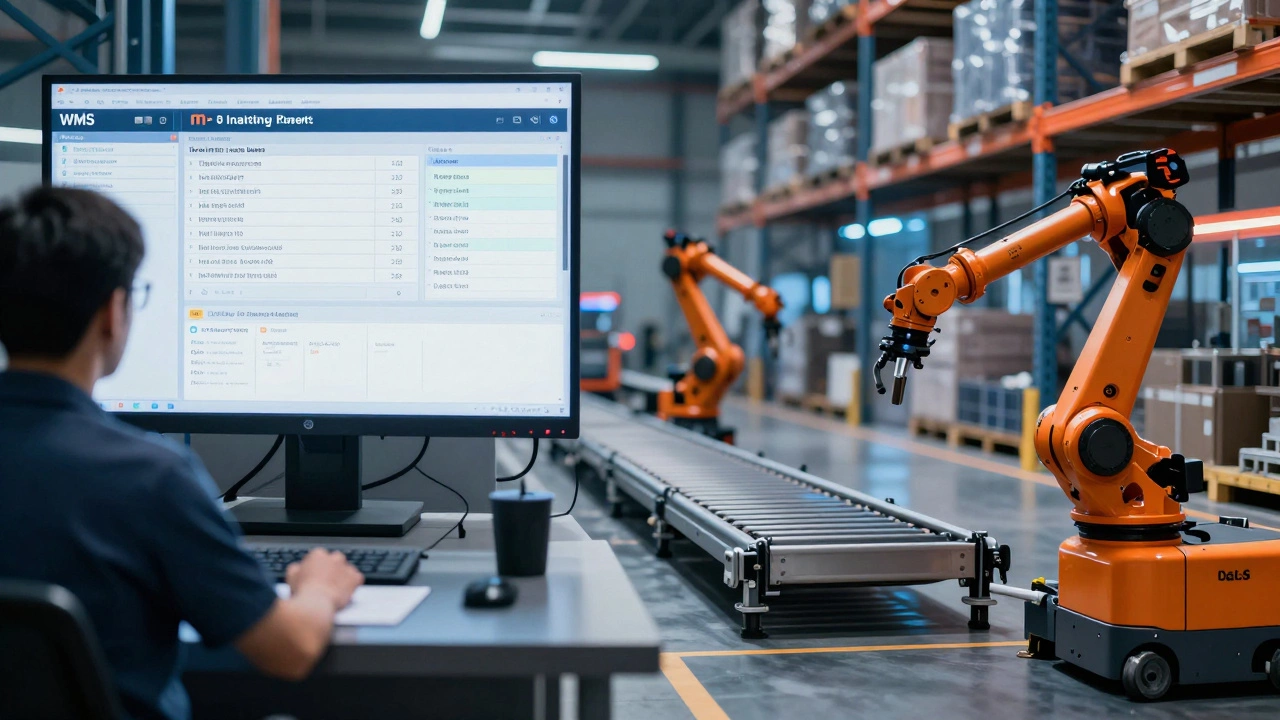

When you think about how packages get from a warehouse to your door, you’re not just thinking about trucks and drivers—you’re thinking about a warehouse control system, a digital brain that directs every movement inside a warehouse, from receiving goods to packing orders. Also known as warehouse management system, it’s the invisible engine behind fast, accurate deliveries. This isn’t just software that tracks inventory—it’s the system that tells workers where to go, when to pick, and which box to grab next, all in real time.

Most people confuse a warehouse management system (WMS), a software layer that organizes inventory data and workflow rules with a warehouse control system. But the truth is, the control system sits lower—it’s the middleman between the WMS and the physical machines. If the WMS says "pick 12 units of Product X," the warehouse control system tells the forklift operator which aisle, which shelf, and which scanner to use. It also talks to conveyor belts, barcode scanners, and automated sorters. Without it, even the smartest WMS is just a spreadsheet with a fancy interface.

Modern warehouses don’t just store stuff—they move it at lightning speed. That’s why companies like Amazon, Walmart, and DHL rely on these systems to handle millions of items daily. A good warehouse control system reduces picking errors by up to 90%, cuts labor costs by streamlining routes, and keeps inventory numbers accurate down to the last unit. It doesn’t just react to orders—it predicts them. If it sees a spike in demand for winter coats, it can reposition stock closer to packing stations before the rush hits.

And it’s not just for big players. Even small businesses using third-party logistics or running their own fulfillment centers need this kind of control. If you’re shipping online, your customers expect fast, correct deliveries. A broken warehouse control system means wrong orders, delayed shipments, and angry customers. The best systems integrate with shipping platforms, ERP tools, and even carrier APIs so everything flows together—no manual data entry, no double-checking, no delays.

What you’ll find in the posts below is a clear look at how these systems actually work, what tools power them (like SAP and Blue Yonder), and how they connect to real-world logistics challenges. You’ll see how smart warehouses use automation, why data matters more than ever, and how even small changes in the system can save hours—or thousands of dollars. Whether you’re running a warehouse, managing logistics, or just trying to understand why your package arrived so fast, this collection gives you the real story—not the marketing fluff.

December 1, 2025

Evelyn Wescott

0 Comments

A warehouse management system (WMS) tracks inventory and orders, while a warehouse control system (WCS) manages automated equipment. Learn how they work together-and when you need one or both.