WMS: Your Quick Guide to Warehouse Management Systems

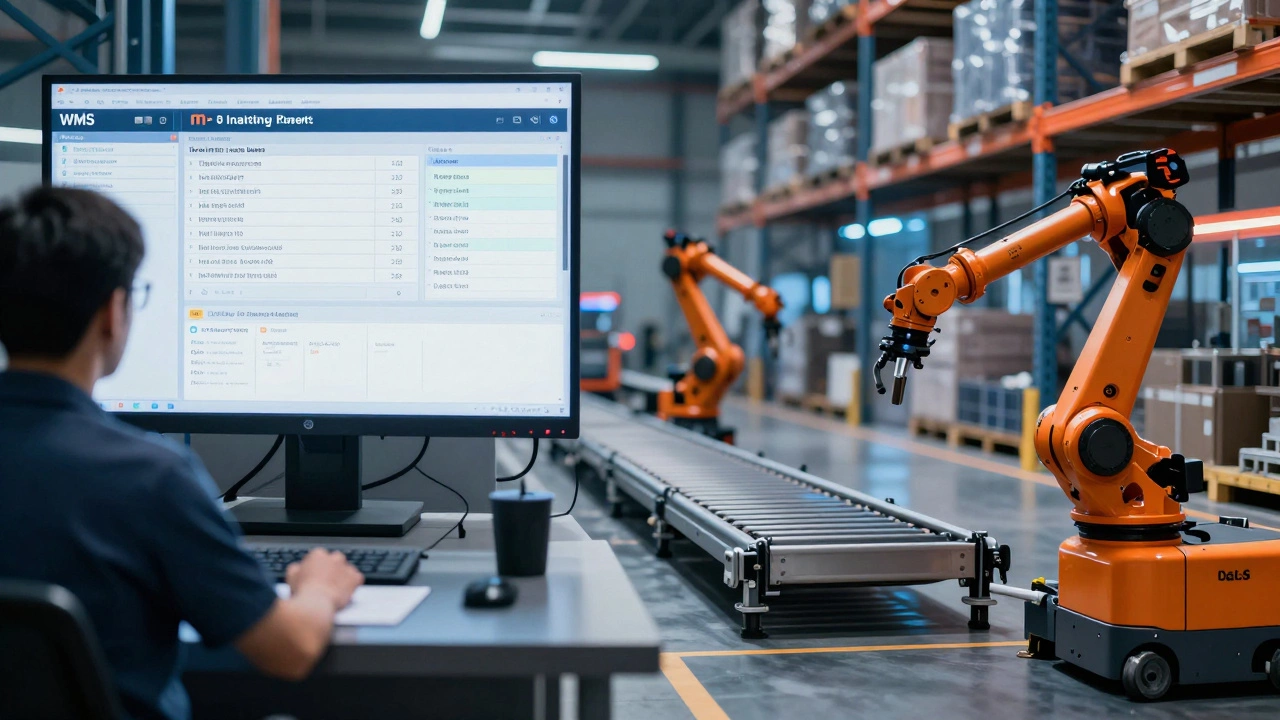

Ever wondered why some warehouses seem to run like clockwork while others are stuck in chaos? The secret is often a solid Warehouse Management System, or WMS. A good WMS tracks stock, directs pickers, and keeps orders moving smoothly. It’s the software brain behind the shelves.

What Exactly Does a WMS Do?

A WMS records every SKU that comes in, tells you where each item lives, and updates counts in real time. When an order pops up, the system generates the fastest pick path, reducing walking time for staff. It also flags low stock, helps schedule replenishment, and can control which dock doors receive shipments.

Choosing the Right WMS for Your Business

Not every WMS fits every operation. Small shops may only need basic inventory tracking, while large distributors want full automation and integration with ERP tools. Start by listing must‑have features: real‑time visibility, barcode support, and reporting. Next, test the user interface – if it feels clunky, training costs will rise.

Look at how the system handles the four main WMS models: stand‑alone, cloud‑based, on‑premise, and hybrid. Cloud solutions offer fast updates and lower upfront costs, but on‑premise setups give tighter control over data. Hybrid options let you mix and match depending on your security needs.

Integration matters, too. Your WMS should talk to your e‑commerce platform, accounting software, and carrier carriers. Seamless data flow prevents duplicate entry and reduces errors. Ask vendors for API documentation and check if they support the shipping carriers you use.

Cost can’t be ignored. Many providers charge per user, per transaction, or a flat monthly fee. Calculate the total cost of ownership, including setup, training, and future upgrades. A cheaper system now may cost more later if it can’t scale.

Finally, consider support. Does the vendor offer 24/7 help? Are there local consultants who understand UK regulations? Good support can save you downtime during peak seasons.

To sum up, a WMS is the tool that turns a messy warehouse into a well‑orchestrated operation. Pick one that fits your size, integrates with your tech stack, and offers solid support. When you get it right, you’ll see faster order fulfillment, fewer mistakes, and happier customers.

December 1, 2025

Evelyn Wescott

0 Comments

A warehouse management system (WMS) tracks inventory and orders, while a warehouse control system (WCS) manages automated equipment. Learn how they work together-and when you need one or both.

December 1, 2025

Evelyn Wescott

0 Comments

A Warehouse Management System (WMS) is software that tracks inventory, directs warehouse workers, and speeds up order fulfillment. Learn how WMS works, who uses it, and why it's essential for modern logistics.

October 14, 2025

Evelyn Wescott

0 Comments

Learn practical steps to identify, analyze, and fix common warehouse problems using layout tweaks, technology, safety protocols, and performance monitoring.

September 18, 2025

Evelyn Wescott

0 Comments

Clear breakdown of SCM software: what each tool does, when you need it, examples, decision criteria, implementation steps, checklists, and FAQs for 2025.

May 31, 2025

Evelyn Wescott

0 Comments

Ever wonder if WMS is just a warehouse tool, or something bigger? This article unpacks the real role of warehouse management systems in the supply chain. Find out what WMS actually does, how it connects all the moving parts, and why smart businesses can’t live without it. You’ll also pick up tips for making a WMS work for you. No jargon, just honest details you can use.

May 26, 2025

Evelyn Wescott

0 Comments

WMS stands for Warehouse Management System, a tool that keeps warehouses running smoothly. This article breaks down what WMS means, how it works, and why it's a must-have for busy warehouses today. You'll get real tips for picking the right system and find out how WMS can actually save time and money. If you're handling products, goods, or shipping, this info will help you get organized and boost efficiency.

March 28, 2025

Evelyn Wescott

0 Comments

Amazon, a leader in global logistics, relies heavily on advanced Warehouse Management Systems (WMS) to efficiently manage its vast operations. This article explores how Amazon uses WMS to optimize its warehouses, streamline processes, and ensure speedy delivery. It delves into Amazon's strategies for inventory management and how technology plays a crucial role in their logistics success. Readers will gain insights into the workings behind Amazon's logistical capabilities and how similar practices can benefit other businesses.