WCS vs WMS: What’s the Real Difference in Warehouse Systems?

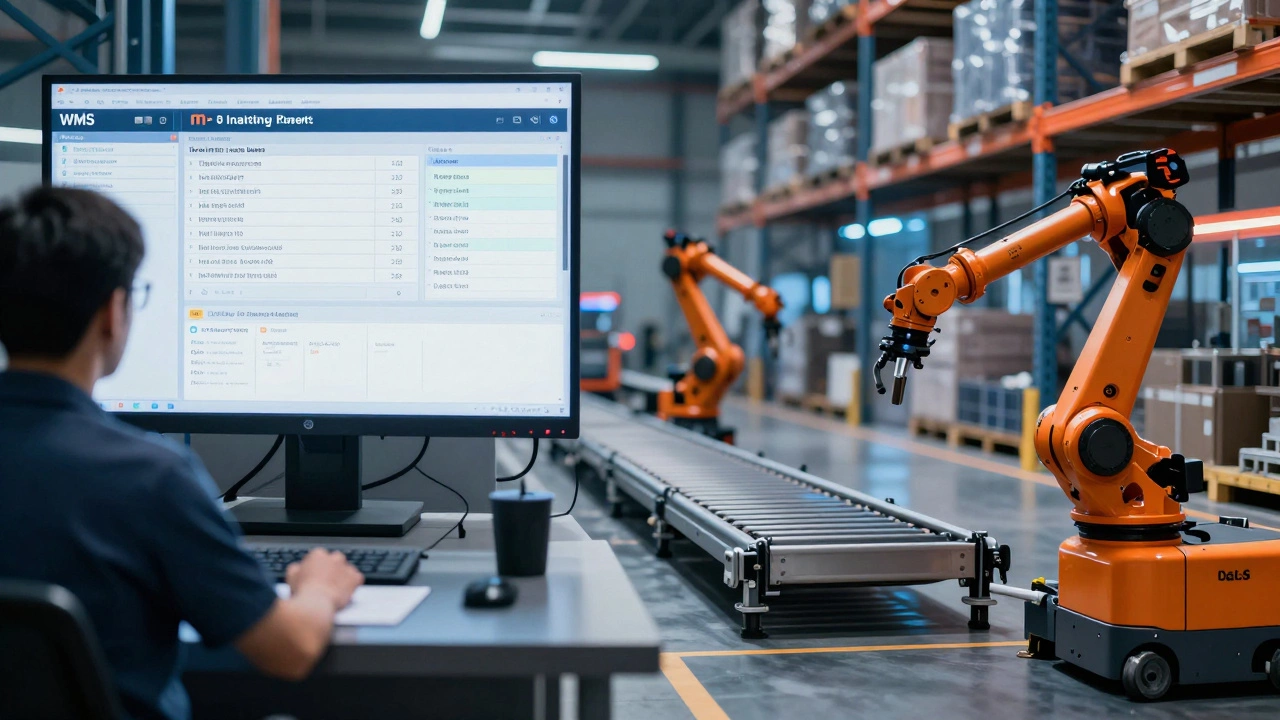

When you hear WMS, a Warehouse Management System is software that tracks inventory, assigns tasks to workers, and manages where things are stored. Also known as warehouse operations software, it’s the brain that decides what gets picked, when, and where. But if you’re running a busy warehouse, you’re probably also hearing about WCS, a Warehouse Control System that directs the physical machines—conveyors, sorters, robotic arms—to move goods fast and accurately. It’s the hands that make the WMS’s plans happen. You don’t need both—but you might be missing out if you think one replaces the other.

The WMS is all about data: it knows you have 47 units of Product X in Bay 3, and it tells a worker to grab them. The WCS doesn’t care about inventory counts—it sees that conveyor belt 5 is backed up and tells the sorter to slow down. One manages information, the other manages motion. Most small warehouses use just a WMS. But if you’re moving hundreds of packages an hour with automated lines, you’re already using a WCS behind the scenes. Companies like Amazon and Walmart don’t just track inventory—they move it at lightning speed, and that’s where WCS steps in. Without it, your WMS might tell a worker to pick 500 items, but the conveyors can’t keep up, and everything backs up.

Think of it like a restaurant. The WMS is the host who knows who’s seated, what they ordered, and when the table is free. The WCS is the kitchen crew—chefs, dishwashers, and food runners—who actually get the food out the door on time. You need both to serve dinner without chaos. If you’re scaling up, adding automation, or dealing with peak season spikes, understanding this split isn’t just technical—it’s financial. A WMS without a WCS might save you money upfront, but it’ll cost you in delays, errors, and frustrated customers. And a WCS without a WMS? That’s like having a robot arm that moves boxes but has no idea what’s inside them.

These systems don’t compete—they collaborate. The WMS sends orders to the WCS. The WCS sends back status updates: ‘Picking complete,’ ‘Conveyor jammed,’ ‘Item scanned.’ That feedback loop is what makes modern warehouses work. And if you’re wondering whether you need one or both, ask yourself: are you moving boxes by hand, or are you moving them with machines? If it’s the latter, you’re already in the WCS game—even if you don’t call it that.

Below, you’ll find real breakdowns of how these systems work in practice—from how SAP integrates with them, to why Amazon’s fulfillment hubs need both, and what happens when you skip one. No theory. No fluff. Just what actually happens in warehouses today.

December 1, 2025

Evelyn Wescott

0 Comments

A warehouse management system (WMS) tracks inventory and orders, while a warehouse control system (WCS) manages automated equipment. Learn how they work together-and when you need one or both.