Product Placement in Logistics: How Brands Use Space to Move More

When you think of product placement, the strategic positioning of goods to drive visibility and sales. Also known as shelf positioning, it's often linked to TV shows and retail stores. But in logistics, it's not about catching eyes—it's about catching time. In warehouses and distribution centers, where every second counts, product placement means putting the right item in the right spot to cut travel distance, reduce errors, and speed up orders. It’s not guesswork. It’s science built on data, demand patterns, and how fast items actually move.

Think of a warehouse like a busy kitchen. If the most-used spices are buried at the back, every cook wastes time hunting. Same in logistics. High-turnover items—like popular e-commerce products or fast-moving retail stock—need to be near packing stations. Low-movers? They can sit farther out. This isn’t just about convenience. Companies using smart warehouse optimization, the process of arranging inventory to maximize efficiency and reduce handling time see up to 30% faster picking times. And it’s not just where things go—it’s how they’re grouped. Items bought together? Put them close. Seasonal goods? Grouped by launch date. This kind of logic turns a storage space into a flow machine.

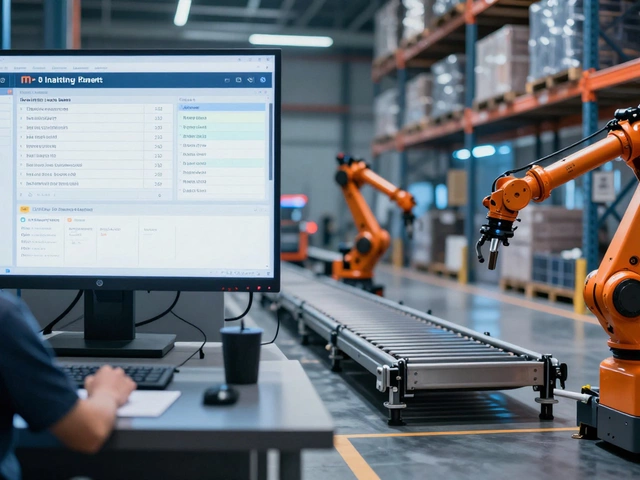

Modern e-commerce logistics, the system of managing online order fulfillment from warehouse to doorstep makes product placement even more critical. With same-day delivery expectations, a misplaced box can delay an entire shipment. That’s why smart warehouses use real-time data from supply chain visibility, the ability to track inventory and movement across the entire delivery network to adjust placements daily. If a product suddenly spikes in sales, the system flags it—moves it closer to the pack line, updates the picker’s app, and even reorders shelf space automatically. No more waiting for a manager to notice. The system learns. It adapts. It acts.

And it’s not just big players doing this. Even small logistics providers are catching on. Why? Because the cost of poor placement adds up fast—extra labor, more fuel, delayed deliveries, unhappy customers. Fixing it doesn’t mean buying expensive robots. Sometimes, it’s just moving a few bins. Or labeling shelves better. Or training staff to spot patterns. The tools are out there—WMS software, barcode scanners, AI-driven analytics—but the real win comes from understanding how space affects speed. And that’s where product placement becomes the quiet hero of logistics.

Below, you’ll find real guides and breakdowns from companies using these exact tactics—from how Amazon rearranges its warehouses to how small couriers cut delivery times by simply changing where they store boxes. No fluff. Just what works.

November 8, 2025

Evelyn Wescott

0 Comments

Learn the 4 P's of logistics-Product, Placement, Price, and Promotion-and how they impact your e-commerce success. Real-world tips for small sellers to improve delivery, cut costs, and boost customer trust.