Logistics is like the circulatory system of the business world, ensuring that goods flow smoothly from one point to another. It's the art and science of managing the way resources are acquired, transported, and stored before reaching the final customer. Imagine logistics as an orchestra, where every piece and player must be perfectly synchronized to create a harmonious outcome.

For those just dipping their toes into this field, it might initially appear overwhelming. However, with a little insight into its main components and processes, you'll find that logistics is all about meticulous planning and execution. In this article, we'll explore the basics of logistics, from the fundamental concepts to the key practices that help manage the flow of goods efficiently.

- Introduction to Logistics

- Key Elements of Logistics

- Supply Chain Management Basics

- Tips for Effective Shipment Coordination

- Common Challenges in Logistics

- Future Trends in the Logistics Industry

Introduction to Logistics

Logistics is a term that often brings to mind images of trucks, ships, and warehouses bustling with activity. However, it's much more nuanced than just these visual stereotypes. At its core, logistics is about steering the journey of goods from their point of origin to the final destination, ensuring that everything happens smoothly and efficiently. This journey involves careful planning, execution, and management, which can be broken down into several critical stages such as transportation, warehousing, inventory management, and customer satisfaction.

Perhaps one remarkable fact about logistics is its influence on global economies. It's intricately linked to the vitality of economic activities worldwide. Without logistics, even the most innovative products would fail to reach consumers, leaving creativity locked away in development hubs. This is why logistics is sometimes referred to as the hidden backbone of trade. The International Monetary Fund estimates that trade enhancements, where logistics play a crucial role, could boost worldwide merchandise trade by approximately 9-10% per year. These statistics emphasize just how significant logistics is in shaping the world we live in today.

One cannot discuss logistics without diving into the concept of the supply chain. Supply chains are the lifelines that connect suppliers, manufacturers, distributors, and retailers in a seamless network. Logistics is the connective tissue that holds this network together, responsible for optimizing delivery times and minimizing costs. In modern times, a well-designed logistics system is critical for maintaining competitive advantages across different industries. Companies like Amazon have revolutionized shipment management through complex algorithms and expansive distribution networks, setting the standard for modern logistical practices.

A look back at history reveals that logistics has been a strategic element for centuries. Ancient civilizations, such as the Egyptians, used rudimentary forms of logistics to build pyramids, employing detailed planning to move massive stones. During World War II, military leaders utilized logistics to gain tactical advantages, coordinating troops and supplies efficiently across vast distances. Today, technology continues to push the boundaries, with AI and machine learning being integrated to optimize delivery routes and predict shipping demands.

Understanding logistics also means recognizing the unique challenges it faces. Environmental concerns and sustainable practices have become focal points in logistics discussions. As climate change grows in awareness, logistics companies are exploring new avenues to reduce their carbon footprint, often turning to electric vehicles and eco-friendly packaging solutions. The logistics sector is not only a vital economic driver but also a key player in environmental stewardship.

In the words of logistics expert John Manners-Bell,

"Logistics is the 'engine' of globalization, and without the freedom to move goods across international borders, the concept of efficient supply chains would simply not exist."This reflection reminds us that logistics is much more than moving goods. It's about crafting the systems that allow our interconnected world to function efficiently, remaining unseen yet indispensable on a global scale.

Key Elements of Logistics

When you break down the world of logistics into its core components, you’ll uncover a tapestry woven from several key elements. At its heart, logistics relies on the critical elements of transportation, warehousing, inventory management, and information flow. Each of these components works in harmony to ensure goods move efficiently from manufacturers to end-users. The pathway of logistics begins with transportation, the backbone that carries the weight of moving goods across countries and continents. It involves a complex array of decisions like choosing the right mode of transport, be it road, rail, air, or sea, and involves logistical planning that considers time, cost, and environmental impacts.

Warehousing is more than just a space to store products; it serves as a strategic hub where goods are carefully managed and monitored. Within these walls, products are not only stored but also packed and repacked, allowing for rapid and organized retrieval. This process is often supported by sophisticated technology to ensure accuracy and efficiency. Inventory management is another critical cog in thewheel, involving the fine balance of supply and demand. It's all about knowing exactly what you have, where it is, and how much more you might need. Successful inventory management prevents excess stock, reduces spoilage, and saves money—all while ensuring there's enough product to meet customer demand.

The smooth flow of information ties all these elements together, acting as the digital nervous system of logistics. This flow is vital, providing real-time insights into tracking shipments, anticipating delays, and ensuring everyone involved is on the same page. This element has been strengthened significantly by advancements in technology. Integrated systems allow for data sharing across platforms, which improves transparency and enhances decision-making within logistics companies. A report from the Council of Supply Chain Management Professionals highlights that "effective communication in logistics may reduce costs by up to 30%." That’s a significant impact, showcasing just how important this element has become.

The Role of Technology

Technology now plays a pivotal role in all these elements, transforming supply chain logistics into a high-tech endeavor. Automated systems streamline processes, from notification alerts that inform you a package is three stops away to drones buzzing in the sky for the last-mile delivery. Utilizing AI and predictive analytics helps logistics companies anticipate and navigate obstacles before they even arise. It’s a fascinating evolution, pushing logistics into the future while solving age-old problems.It’s curious to note how all these interconnected parts must function seamlessly together. If just one element is mismatched or ignored, the chain may break, leading to disrupted services and unhappy customers. Holding all these elements in a delicate balance is essential for efficiency and productivity in today's fast-paced world. As you can see, the logistics landscape is vast and nuanced, rich with opportunity for innovation and improvement. To successfully navigate it, understanding and embracing these core elements will be your guiding compass.

Supply Chain Management Basics

When we talk about supply chain, we're essentially referring to a network that connects suppliers to consumers, ensuring products are delivered effectively and efficiently. Picture it as the intricate communication lines between each segment of the business chain that squeezes out inefficiencies and optimizes production. Each company within this chain plays a crucial role - from the raw material suppliers to manufacturers, and then onto distributors and retailers. Seamless collaboration among these players ensures that products reach the end consumer in perfect condition and on time. Keeping all this in sync avoids unnecessary hurdles and ensures the supply chain remains robust.

Supply Chain Management (SCM) integrates core business activities, aligning demand with supply and maintaining optimal inventory levels. This involves myriad processes including procurement, production, and logistics. Each phase must remain transparent, allowing for quick modifications should any disruptions occur. For instance, a well-managed supply chain can proactively anticipate and mitigate risks, thus avoiding delays. It is here that technology plays a pivotal role, providing real-time insights that are invaluable for Supply Chain Managers.

"The best supply chains aren't just fast and cost-effective, they're also agile and adaptable," says expert Martin Christopher from Cranfield University.

The rise of technology has transformed SCM, allowing for better coordination and efficiency. With data analytics at the core, businesses can forecast demand, manage stock, and improve route efficiency. Techniques such as Just-In-Time (JIT) ensure only what's necessary is produced, reducing waste and lowering costs. Moreover, supply chains that embrace sustainability practices significantly appeal to environmentally-conscious consumers, a crucial marketing edge in today's world. By implementing strategies that reduce carbon footprints, companies can not only cut costs but also boost brand reputation.

Key Components of Supply Chain Management

SCM comprises several components that need meticulous attention. Demand management is the first step, where companies predict customer demand patterns using consumer data to streamline their operations. This prediction aids in ensuring that inventory levels are perfectly optimized. Procurement follows next, involving sourcing raw materials from the best suppliers who offer both quality and cost-effectiveness. A collaborative relationship with suppliers is key to successful procurement management. Then comes the production stage, where products are manufactured and assembled. Proper quality control measures must be in place to ensure products meet the desired standards before moving forward in the chain.

Lastly, comes the logistics aspect, which is about timing and precision. Within logistics, products are stored, handled, and transported to retailers or customers. It's often referred to as the 'last mile' delivery, denoting the critical final stage that impacts customer satisfaction. A deeper insight into these components highlights that SCM is all about visibility and efficiency. It'll be fascinating to witness the dramatic evolutions in future logistics technologies and how they shape the dynamics of the supply chain.

| Component | Importance |

|---|---|

| Demand Management | Ensures products are in demand and helps in stock optimization |

| Procurement | Secures quality products at cost-effective pricing |

| Production | Involves manufacturing and quality control to meet standards |

| Logistics | The process of storage, handling, and delivery |

Tips for Effective Shipment Coordination

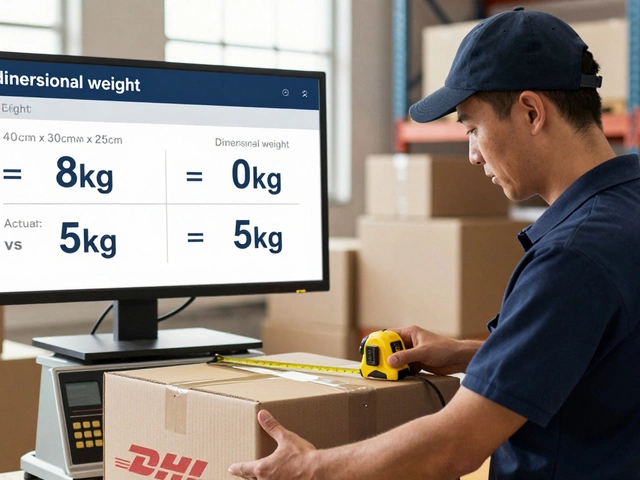

Coordinating shipments effectively is a key part of logistics that directly impacts customer satisfaction and operational efficiency. Successful shipment coordination involves meticulous planning, communication, and the use of technology to streamline processes. One fundamental tip includes leveraging technology. Many logistics companies now rely on advanced software to track and manage shipments in real time. This technology provides visibility across the supply chain, allowing for immediate adjustments when delays or issues arise. Using such tools can significantly reduce errors in delivery and inventory management, ultimately saving both time and resources.

Developing strong relationships with carriers and partners can make all the difference in shipment coordination. When everyone involved in the shipping process communicates openly, it results in quicker problem resolution and more reliable service. It’s also essential to set clear expectations concerning timelines and processes. Keeping all parties updated on shipment statuses helps in proactive decision-making, which can prevent potential bottlenecks in the logistics pipeline.

A well-structured organization is another aspect that can enhance shipment efficiencies. Creating a detailed shipping plan that includes schedules, responsibilities, and contingencies will help keep things on track. Monitor each step of the shipment process from picking and packing to loading and delivery, as this can highlight areas for improvement. Ensure documentation is accurate and complete to prevent unnecessary delays at customs or checkpoints. To quote logistics expert Tim Collins,

"Precision in planning and consistency in execution are the real keys to effective shipping."

Keep track of performance metrics, such as delivery times, cost per shipment, and number of incidents or delays. Gathering and analyzing this data can provide actionable insights for future improvements and adjustments. Adapting quickly to feedback and changes in the market environment will keep your logistics strategy robust and responsive. Highlighting areas where costs might be cut without compromising service quality is invaluable for both small and large operations. Below is a simple table showing key performance indicators (KPIs) that logistics companies often monitor:

| Key Indicator | Description |

|---|---|

| On-time Delivery Rate | Measures the percentage of deliveries completed on schedule |

| Average Delivery Cost | The average expense incurred for delivering goods |

| Inventory Turnover Rate | How often inventory is sold and replaced over a period |

By staying informed and methodical, even beginners in logistics can develop effective shipment coordination techniques. Remember, logistics is a dynamic field, but with strategic foundations, navigating its complexity becomes considerably more manageable.

Common Challenges in Logistics

When diving into the world of logistics, beginners might realize it's not just about moving items from Point A to Point B. There are many hurdles to overcome, each demanding its own set of problem-solving skills. Just ask any logistics professional, and they'll tell you that unpredictability is almost guaranteed. From fluctuating fuel costs to unexpected weather conditions, many factors lie outside one's control. This uncertainty makes planning a robust logistics strategy quite challenging. Moreover, new technologies are rapidly transforming the logistics landscape. While innovations like AI and machine learning offer immense potential, they also require significant adaptation and training efforts. Navigating these tech advancements while managing day-to-day operations can seem like a Herculean task for companies.

Another notable challenge involves maintaining transparent and efficient communication across all links in the supply chain. With so many parties involved—suppliers, manufacturers, transporters, and retailers—it’s easy for miscommunications to snowball into bigger issues. Any lag in information sharing can lead to costly inefficiencies. To combat this, logistics companies often invest in advanced software solutions. Yet, integrating these systems with existing processes is not always straightforward. According to a study by the Council of Supply Chain Management Professionals, nearly 60% of logistics firms cited poor communication as a major bottleneck. As such, developing strategies to enhance communication lines is critical for smooth operations.

Capacity constraints represent another persistent challenge, especially during peak seasons. Just imagine planning the distribution of goods when warehouses and transportation fleets reach maximum capacity. This limitation requires precise forecasting and demand planning to avoid bottlenecks. Some businesses cope by forging partnerships with third-party logistics providers, which can offer additional resources during crunch times. Yet, even these external alliances come with their own set of challenges, such as ensuring emergency freight coverage or tracking remote warehousing facilities.

"The supply chain is the backbone of the economy, and it's only as strong as its weakest link," remarked Tom Jones, a logistics expert from the Global Supply Chain Institute.

Beyond these operational concerns, logistics companies face the growing pressure of adhering to environmental regulations. With the world becoming more eco-conscious, companies are tasked with reducing their carbon footprint. This could involve adopting electric or hybrid delivery vehicles, implementing green warehousing practices, or optimizing routes to curtail emissions. Although such initiatives help safeguard our planet, they often require substantial upfront investments, both in terms of finances and reshaping organizational culture.

To illustrate these challenges more clearly, let's consider a hypothetical scenario where a company faces multiple obstacles simultaneously:

- Sudden spike in orders leading to capacity crunch

- Breakdown of a truck due to poor maintenance

- Delayed shipment caused by inclement weather

- Inconsistent communication with a new supplier

- Struggle to incorporate a new digital tracking system

Addressing such issues effectively demands robust contingency planning. Many logistics professionals advocate for regular scenario simulations or training programs to prepare teams for real-world challenges. In the unpredictable realm of logistics, adaptability and foresight are key. Tackling these challenges head-on ensures that the industry continues to evolve, meet the demands of an ever-changing market, and maintain a crucial role in the global economy.

Future Trends in the Logistics Industry

As the global economy continues to evolve, logistics is charting new territories with emerging trends reshaping the industry landscape. First on the horizon is the integration of technology, which has been both inevitable and transformative. The adoption of advanced technologies like artificial intelligence and the Internet of Things (IoT) is streamlining processes and enhancing efficiency. AI is not only helping with predictive analytics to foresee demand spikes but also optimizing routes to reduce fuel costs and delivery times. Meanwhile, IoT-enabled devices are ensuring real-time tracking of goods, providing transparency and visibility that customers have come to expect.

The need for sustainability is another game-changer in the logistics industry. As environmental concerns grow, logistics companies are actively seeking ways to reduce their carbon footprint. This effort manifests in the development of eco-friendly transportation options, like electric delivery vehicles and greener alternative fuels. A commitment to sustainability not only helps the planet but also meets the rising consumer demand for environmentally conscious business practices.

Industry leader John Smith once said, "Sustainability isn't just an option; it's a necessity."This sentiment perfectly captures the direction companies are heading, as they embrace green logistics solutions.

In addition to tech and sustainability, the rise of e-commerce is another critical shift that's dramatically altering the logistical landscape. Online shopping has exploded, driving the need for nimble logistics solutions that can handle last-minute deliveries and returns. Warehousing is adapting by becoming more automated and strategically located closer to urban centers to reduce the lag time associated with deliveries. Efficiency is key here, and it's forcing an evolution in how logistics companies operate. Shipment management systems are being upgraded to support these changes and ensure orders are processed swiftly.

The global landscape for logistics is also experiencing structural changes due to geopolitical factors. Trade policies, tariffs, and international relations continuously impact how goods are transported across borders. Companies are re-evaluating their supply chains to be more resilient against disruptions, whether caused by political tension, natural disasters, or pandemics. Many are adopting a more flexible approach, diversifying sources, and employing contingency plans as standard practice to safeguard against unforeseen challenges. This adaptability is crucial in maintaining the seamless flow of goods across the globe.

Finally, consumer expectations are reshaping the logistics landscape drastically. With digital communication providing constant updates, consumers now want faster, more reliable services. This expectation has driven the rise of same-day and next-day delivery services, pressuring logistics companies to rethink their traditional models. It is about creating strategies that can meet these demands efficiently without compromising quality or cost-effectiveness, which often involves innovative storage solutions and leveraging data for smarter storage decisions. These consumer influences are a major driver in logistics, necessitating agility and creativity in logistics management.