Forget those stories about tiny garages turning into giant corporations. The real jaw-dropper is how some of the world’s biggest companies work behind the scenes, storing and shipping everything from TVs to sneakers in spaces so vast they’re almost their own neighborhoods. One record-breaking warehouse stands above the rest: a behemoth that stores more products than a small country probably owns. But who runs this fortress of goods? And why should anyone outside the world of logistics even care?

The Colossal Facility: Measuring the Biggest Warehouse

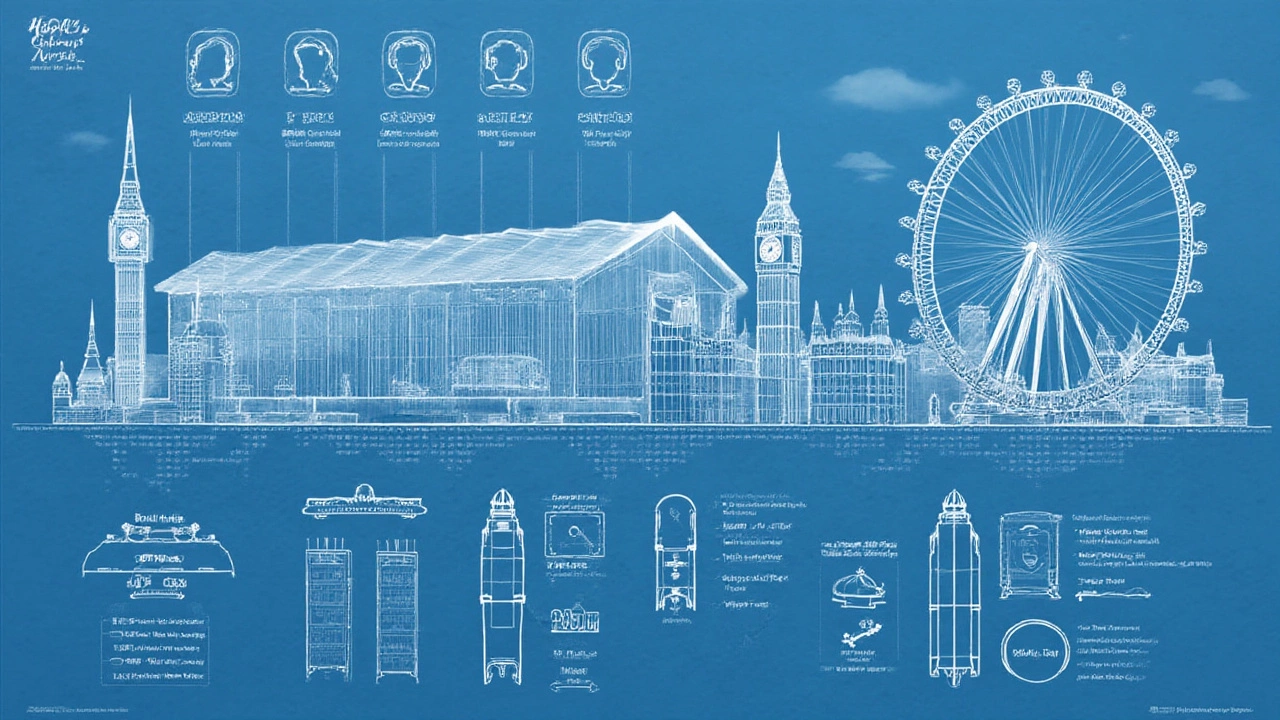

Warehouse sizes seem almost cartoonish until you spot the numbers. The biggest warehouse in the world is the Boeing Everett Facility in Everett, Washington, USA. This single building sprawls across a monstrous 399,480 square meters (4.3 million square feet). That’s roughly 80 football fields lined up side by side. It’s so immense that people joke about needing bikes just to travel from one end to the other. If you tried to walk across it at an average pace, you’d need over 30 minutes—no joke.

This isn't just a warehouse for boxes and crates. Boeing built and designed this cavernous space to put together their enormous airplanes—the 747, 767, 777, and even the new 787 Dreamliner. Housing entire aircraft under one roof? That’s another level of big.

But don’t let size alone fool you. Massive distribution centers run by retailers and logistics giants are closing the gap fast. Tesco’s Distribution Centre in Ireland, Target’s Import Warehouse in California, and Amazon’s Jubilee warehouse in Tennessee all rank, each holding over 185,000 square meters (2 million square feet) of stock, sometimes stacked four floors high.

If you stacked all the high shelves in just one of these mega-facilities, the height would beat many skyscrapers. Every day, thousands of workers and robots pick, pack, and load goods at a dizzying pace—and the trend is only getting bigger.

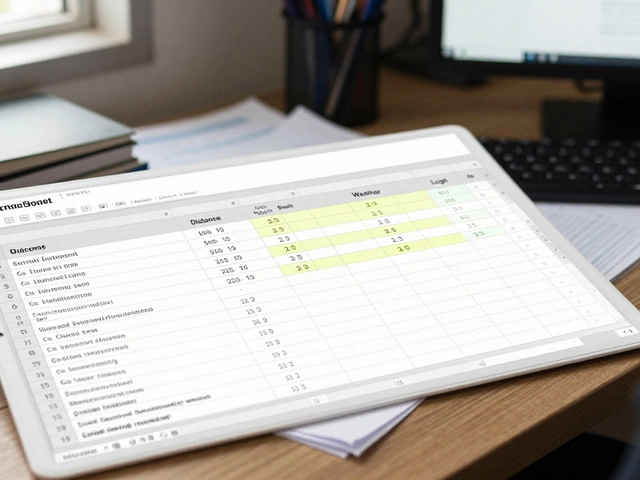

| Warehouse Name | Location | Area (sq. m.) | Main Use |

|---|---|---|---|

| Boeing Everett Facility | Washington, USA | 399,480 | Aircraft Assembly |

| Amazon Tennessee | Tennessee, USA | 185,806 | Retail Distribution |

| Tesco Distribution Centre | County Meath, Ireland | 122,000 | Grocery Logistics |

| Target Import Warehouse | Lacey, Washington, USA | 185,800 | Retail Distribution |

Who Actually Owns the Biggest Warehouse?

Here's the answer a lot of people don't see coming: Boeing owns the world’s largest warehouse. Unlike brands like Amazon, which lease or manage most of their monstrous facilities, Boeing built and owns the Everett plant outright. Boeing is a household name, mostly thanks to their passenger planes, but they also invented the warehouse-to-end-all-warehouses out of pure necessity. Planes don’t just pop out of thin air. They’re born in giant, climate-controlled halls crammed with tools, parts, and teams working around the clock.

Want to know why they need so much space? A single Boeing 747 has a wingspan over 64 meters. To assemble one requires not just room for the body, but cranes, tracks, and support equipment. Storing that many gigantic airplane parts means dealing with bulky, awkwardly shaped goods that don't fit in normal-sized buildings.

Most companies can only dream of owning such an outrageous place. Take Amazon for example—its Tennessee fulfillment center is company-owned and massive by retail standards, but it doesn't compare to Boeing’s airplane stronghold. In fact, many modern distribution centers are either leased or sold in real estate deals, with logistics companies running operations. Boeing keeps the Everett site close to its chest, seldom leasing it or sharing the space with outsiders.

If you’re picturing a dreary, echoing block filled with crates, you’ve got it all wrong. The Everett plant pumps with energy. Specialists zip from station to station on scooters and little vehicles. Drones even join the party for tiny deliveries inside, sometimes carrying as much as 10 kilograms at a time. It’s not just the biggest—it’s a symbol of how size and specialization come together in modern industry.

Boeing's hold on the biggest warehouse is so strong that rival facilities are called “airplane hangars” or “mega-warehouses” but rarely reach Everett-scale. Until someone decides to build a warehouse for rocket ships, this crown stays with Boeing.

Why Size (Still) Matters in Warehousing

This isn’t just a who’s-got-the-bigger-box-contest. Why do companies keep aiming for more square meters? Well, the answer is simple: money and speed. The bigger the warehouse, the more stuff you can store, pack, and ship. And let’s not forget efficient routing. You can stock more products closer to where customers live, shaving days off deliveries—huge in a world that no longer tolerates late packages.

Take Amazon’s record holiday shipping stats. In December 2023 alone, Amazon shipped over 1.5 billion products worldwide in a single month, according to their press announcement in January 2024. With so many buyers clicking ‘order now,’ the only way to manage the chaos is with massive warehouses capable of handling truckloads, trainloads, and even flights of goods each hour.

Here’s a secret: building up (multiple floors) can be even smarter than building out. Warehouses like Alibaba’s Cainiao Smart Logistics Hub in China have gone vertical, stacking shelves up to 30 meters high, and using automated robots to navigate between tiny gaps. This lets companies squeeze even more out of every square meter, saving on real estate costs and cutting the time it takes to get goods from shelf to truck.

But big isn’t always easy. Bigger warehouses need more advanced fire suppression, precise temperature controls, backup power, and mind-blowing security (think facial recognition cameras, not just locked doors). If a disaster hits, recovering from loss in a mega-warehouse is way pricier than a local storage shed.

Want a tip on spotting a world-class warehouse? Look for those that have their own dedicated freight train stops or airstrips nearby. These aren’t “warehouses” in the classic sense, but logistics engines that move everything from the world’s laptops to avocados—sometimes in the space of a few hours.

Secrets Inside the Largest Warehouse

The Boeing Everett Facility is not open for just anyone to wander around, but guided tours (pre-Covid, at least) gave rare glimpses into operations. What stands out is the scale, but also the mind-boggling organization. Thousands of workers, subcontractors, and robots all work in careful choreography, assembling planes from floor to ceiling—literally. Some components arrive from across the world and move through hundreds of steps before they’re loaded onto a plane and flown out from the adjacent airport.

This is not your average warehouse full of cartons and conveyor belts. Machines hoist parts weighing several tons; floors are reinforced to handle the weight of a half-built jet; massive cranes track along the roof, moving wings and engines with pin-point accuracy. Managers rely on real-time data, with monitors showing inventory, safety stats, and project timelines. RFID tags (radio-frequency identification) help keep track of parts as they crisscross the hangar. A missing bolt could mean millions in delays, so every step is tracked, measured, and checked.

Here’s a tasty fact: the Everett Facility even houses a cafe and showers for staff, since many spend 10–12 hour shifts inside this controlled climate ‘city.’ Tech-savvy fans will love knowing that workers use tablets synced to a local network, pulling up aircraft instructions, checklists, and blueprints on the fly. Oh, and yes—there’s Wi-Fi, but it’s locked down so tight you’d need a codebreaker to peek inside.

Security is a big deal. Cameras pan every hallway; access points use smart cards. In 2022, Wired Magazine described the warehouse as "more like a biosphere than an industrial plant—completely artificial, where temperature and light are tuned for peak human and machine performance."

"The Everett plant isn’t just a warehouse. It’s a living organism, a carefully balanced ecosystem of machines, parts, and people," – Wired Magazine, July 2022

Boeing’s facility even helps test new ideas in logistics and automation before they spread to other factories. Smart forklifts, low-emission heating, eco-friendly cleaning—these green tweaks are helping Boeing shrink its carbon footprint, even as it builds giants that regularly circle the planet.

How the Biggest Warehouses Influence Our Everyday Life

Feels like the especially big warehouses are a world away from daily life, right? But every time you order shoes online or see a new plane flying overhead, those mega-warehouses are quietly making it happen. They’re the bridge between manufacturers, sellers, and buyers—pulling the strings in the background so our world doesn’t slow down.

The sheer size and efficiency of the Boeing Everett Facility has driven rivals to dream bigger. In 2024, Indian e-commerce titan Flipkart broke ground on a 200,000-square-meter distribution center in Hyderabad, aiming to rival Amazon and scale up India’s retail infrastructure. In China, the aforementioned Alibaba hub reportedly sorts and ships up to 1.5 million packages daily—and that’s just one site among many.

For local economies, landing a mega-warehouse is almost like winning the lottery. They bring thousands of jobs, sometimes sparking new housing and public transport upgrades to handle their workforce. In the U.S., cities in Ohio, California, and Texas practically compete to attract Amazon, Walmart, and FedEx super-centers—offering tax breaks and help with new roads, hoping to get their slice of the global delivery pie.

If you’re curious about visiting or working inside one, here’s a tip: most major companies post videos online showing day-in-the-life action. These aren’t Hollywood trailers—they’re raw clips of forklift ballets, rows of robots, and supervisors marshalling armies of pickers and packers. Watching for a few minutes gives you a true sense of the relentless energy and scale.

Behind the glare of jet engines or the ping of your next doorstep delivery, the world’s biggest warehouses are always awake, humming and stacking, ensuring everyone gets what they want, exactly when they want it. The future promises even more automation, even more towering shelves, and possibly a new contender rising to finally out-big the mighty Everett Facility. Until then, all bets are on Boeing’s stronghold, the reigning champion of the world’s warehouse wonders.